Printed Circuit Board (PCB) manufacturing has become an essential part of the manufacturing industry as electronic devices continue to proliferate. In recent years, the digital transformation of the manufacturing industry has brought significant opportunities and challenges to the PCB manufacturing sector. MacroFab, a company that specializes in PCB assembly, is at the forefront of this transformation, providing cutting-edge solutions to meet the growing demands of the industry.

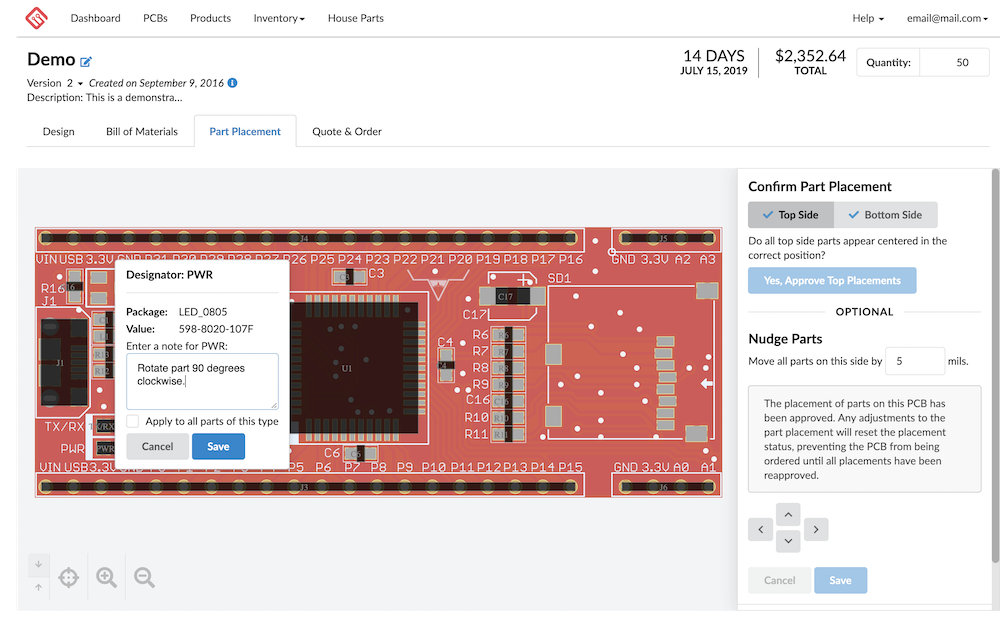

MacroFab’s innovative approach to PCB assembly includes the use of automated assembly lines, advanced software, and machine learning algorithms. These technologies allow the company to produce high-quality PCBs with greater efficiency and precision than traditional manufacturing methods. The automated assembly lines, for example, can handle high volumes of PCBs with minimal human intervention, reducing the likelihood of errors and increasing production speed.

The use of advanced software and machine learning algorithms also allows MacroFab to optimize its manufacturing processes. By analyzing data on production processes and identifying areas of inefficiency, the company can improve its operations and reduce costs. This, in turn, allows MacroFab to offer its customers competitive pricing while maintaining high-quality standards.

Another advantage of MacroFab’s approach to PCB assembly is its ability to customize its solutions to meet the specific needs of its customers. Whether it’s a small-scale project or a large-scale production run, MacroFab can tailor its services to meet the unique requirements of each customer. This flexibility is essential in today’s fast-paced manufacturing industry, where agility and responsiveness are crucial for success.

In conclusion, the digital transformation of the manufacturing industry has brought significant changes to the PCB manufacturing sector, and companies like MacroFab are leading the way in this transformation. With their innovative approach to PCB assembly, advanced technologies, and customer-centric approach, MacroFab is well-positioned to meet the growing demands of the industry and help shape its future.

As a manufacturer of PCB etching machines, you understand the critical role that this equipment plays in the manufacturing process. With the increasing demand for electronic devices, the need for high-quality PCBs has never been greater. MacroFab, a leading company in the PCB assembly industry, has demonstrated how innovative solutions and advanced technology can meet this demand while providing cost-effective solutions for its customers.

MacroFab’s use of automated assembly lines, advanced software, and machine learning algorithms has revolutionized the PCB assembly process. By automating the assembly process, MacroFab can handle high volumes of PCBs with minimal human intervention, reducing the risk of errors and increasing production speed. The use of advanced software and machine learning algorithms allows MacroFab to optimize its manufacturing processes by analyzing data and identifying areas of inefficiency.

The company’s customer-centric approach allows it to customize its services to meet the specific needs of each customer, from small-scale projects to large-scale production runs. This flexibility is crucial in today’s fast-paced manufacturing industry, where agility and responsiveness are essential for success.

As a PCB etching machine manufacturer, you can learn from MacroFab’s success and apply their principles to your business. By investing in innovative solutions and advanced technology, you can improve the efficiency and precision of your machines, providing cost-effective solutions for your customers. Additionally, you can adopt a customer-centric approach, providing customized services that meet the unique needs of your customers.

In conclusion, the case of MacroFab’s success in the PCB assembly industry provides valuable lessons for PCB etching machine manufacturers. By investing in innovation and advanced technology and adopting a customer-centric approach, you can differentiate your business and provide high-quality, cost-effective solutions for your customers. As the demand for electronic devices continues to grow, it’s essential to position yourself as a leader in the industry, providing solutions that meet the needs of your customers and help shape the future of PCB manufacturing.

Conclusion: The digital transformation of the manufacturing industry has brought significant changes to the PCB manufacturing sector. The success of MacroFab in the PCB assembly industry provides valuable lessons for PCB etching machine manufacturers. By embracing innovation and a customer-centric approach, manufacturers can differentiate themselves and provide high-quality, cost-effective solutions for their customers. As the demand for electronic devices continues to grow, it is essential to position oneself as a leader in the industry, providing solutions that meet the needs of customers and help shape the future of PCB manufacturing.