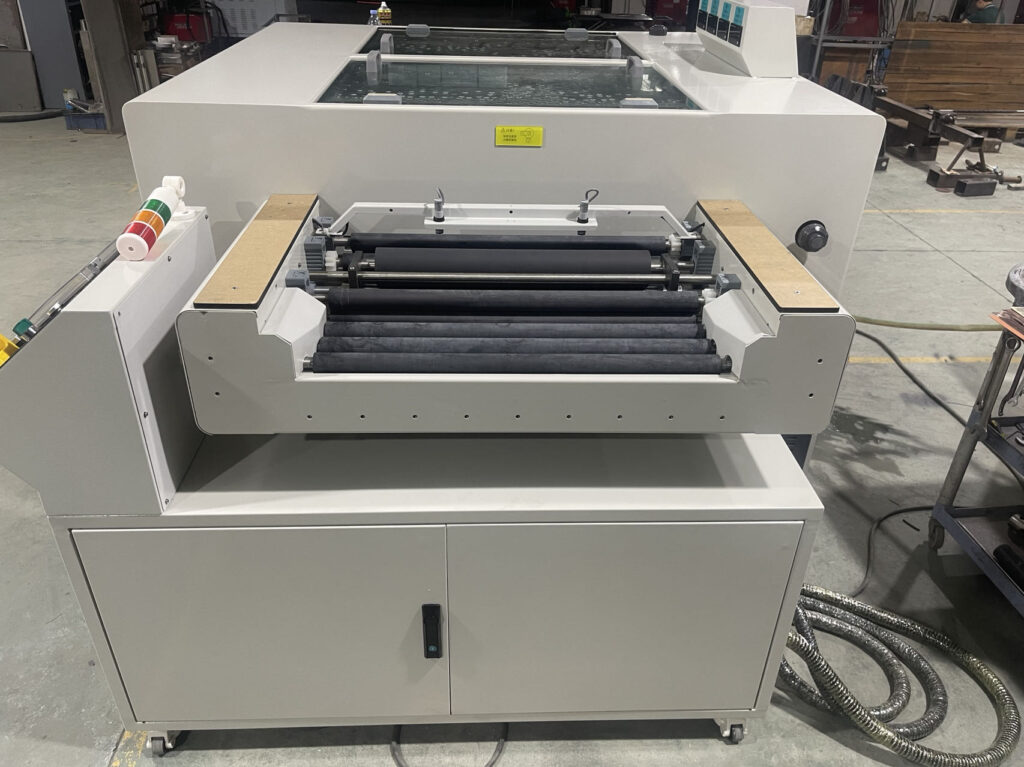

Automatic PCB milling machine

Manual PCB milling machine

Automatic PCB milling machine Specifications

Please note: There is no fixed size, speed or efficiency for the Dragon milling machine, this will need to be customised to suit your needs. The following parameters are for reference only.

|

birthplace

|

China

|

|

Guangdong

|

|

|

brand

|

Dragon Etching

|

|

core inter-layers

|

2 mil(where 1 mil is equal to 0.001 inches.)

|

|

PCB construction where

|

250 mil

|

|

working width

|

500/600/700/800MM customized

|

|

high

|

900-1100mm customized

|

|

Thin Material Transport for PCB

|

1m-100m depends on output

|

|

Voltage

|

380V/415V/440V customized

|

|

Material

|

Polypropylene 12/15/ 20MM

|

|

Specificities

|

Flexible reel-to-reel Kapton,Rigid FR4,1~100m,2 mil material can be transported no problem(OEM)

|

|

heating type

|

SST316 titanium heater

|

|

Modular metal

|

SST316 titanium material

|

|

apply to

|

high precision etching (Wet Processing for PCB)

|

|

Common Processes

|

|

|

Common Chemicals Etchant

|

|

|

After Warranty Service

|

Video technical support, online support, spare parts

|

Pcb milling Machine Features

Factors you need to consider when buying a Pcb Etching Machine

Metal etching machines are essential tools in the manufacturing industry, allowing for the precise and efficient removal of metal material to create intricate designs and patterns. When it comes to choosing a metal etching machine, there are several important performance features and effects to consider.

One crucial performance feature is the machine’s precision. The precision of a metal etching machine determines the accuracy with which it can remove metal material, allowing for the creation of intricate designs with clean, crisp lines. Additionally, a high-precision machine can produce consistent results across a range of materials and thicknesses.

Another key performance feature is speed. The speed of a metal etching machine affects the efficiency with which it can remove material, allowing for faster production and turnaround times. Additionally, a fast machine can help reduce production costs and increase throughput.

The quality of the etched finish is another important consideration. A high-quality finish is essential for producing parts that meet or exceed customer expectations. A good metal etching machine will produce clean, smooth edges, and a consistent finish across the entire surface.

Other factors to consider include the versatility of the machine, its ease of use, and its reliability. A versatile machine can be used for a range of applications, while an easy-to-use machine can save time and reduce the risk of errors. Finally, a reliable machine will minimize downtime and reduce maintenance costs.

In summary, when it comes to choosing a metal etching machine, precision, speed, finish quality, versatility, ease of use, and reliability are all crucial performance features and effects to consider. By choosing a machine that excels in these areas, you can ensure that your manufacturing processes are optimized for efficiency, accuracy, and high-quality results.

We offer after-sales solutions

A video to let you know the working process of PCB metal etching

VECO’s video to learn what metal etching is

Comments related to etching technology:

From chadr2604:

There is another way it involves stacking many layers of very thin material with an There is another way it involves stacking many layers of very thin material with an adhesive, pressing the stack, then either stamping or punching the blank then heating it to release the adhesive. The parts will not be as accurate the tolerance is limited to about .002″ but if its good enough its much faster.If you try to cut that stack with a laser you will just start a fire we had an aluminum fire trying that.

Why do people who use laser cutting machines choose etching machines?

- Absorption of laser energy: Certain materials have a high absorption rate for the laser energy used in the cutting process. When the laser beam interacts with the material, it gets absorbed rather than being reflected or transmitted. This high absorption can generate intense heat, potentially leading to thermal runaway and ignition.

- Combustible properties: Some materials possess combustible properties, such as high flammability or low ignition temperature. When exposed to the concentrated heat generated by the laser, these materials can reach their ignition point, resulting in combustion or fire.

Difference between traditional sheet metal precision processing VS Chemical etching sheet metal processing

Modern precision sheet metal fabrication includes a common technique known as etching, which differs from traditional sheet metal fabrication in several ways. Here are some key differences between etching and traditional precision sheet metal fabrication:

- Principle: Traditional sheet metal fabrication typically involves mechanical processes such as cutting, bending, and punching to shape and form metal sheets. Etching, on the other hand, is a chemical process that uses specialized etchants to selectively corrode the metal surface, achieving precise etched patterns and features.

- Accuracy and Complexity: Etching offers advantages in terms of precision and complexity. By controlling the composition, concentration, temperature, and etching time of the etchant, extremely fine etching can be achieved with accuracy down to sub-micron levels. Additionally, etching allows for the creation of intricate geometries, microstructures, and patterns that may be difficult to achieve using traditional mechanical methods.

- Processing Speed and Cost: Etching generally offers faster processing speeds, particularly in large-scale production. In comparison, traditional mechanical fabrication methods may require more time and cost to achieve the same level of precision and complexity.

- Materials Compatibility: Etching techniques are applicable to a range of metal materials, such as copper, aluminum, stainless steel, and titanium. Traditional sheet metal fabrication methods may have limitations when it comes to certain materials or thicker metal sheets.

- Design Flexibility: Etching provides greater design flexibility. By incorporating techniques like photolithography or screen printing during the etching process, complex patterns and structural designs can be achieved. This makes etching suitable for applications in microelectronics, optical devices, microfluidic devices, and more.

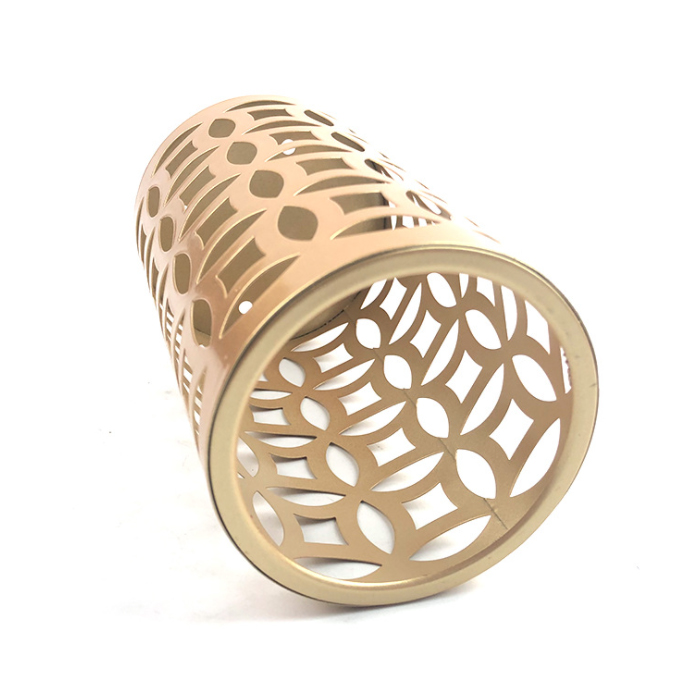

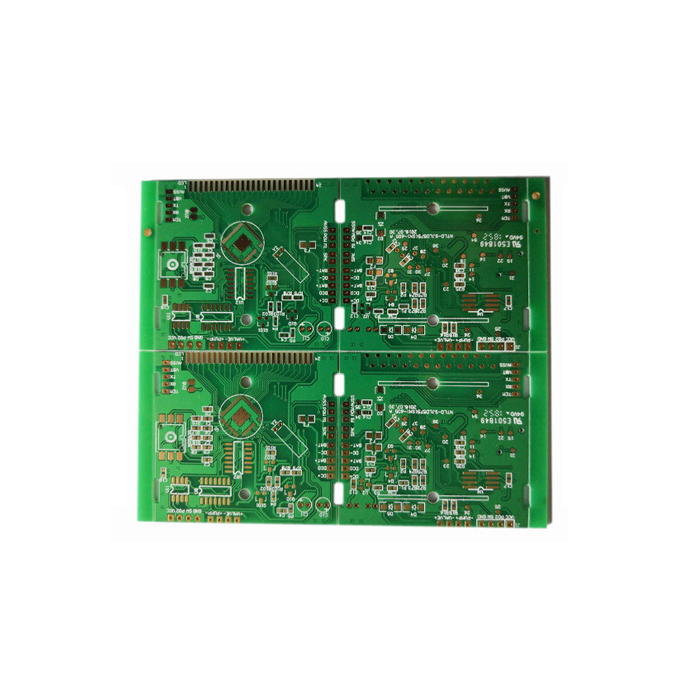

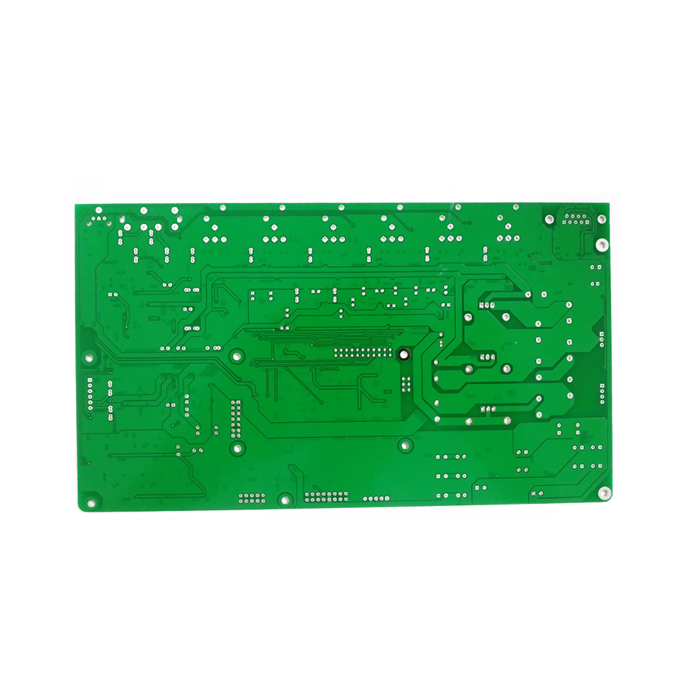

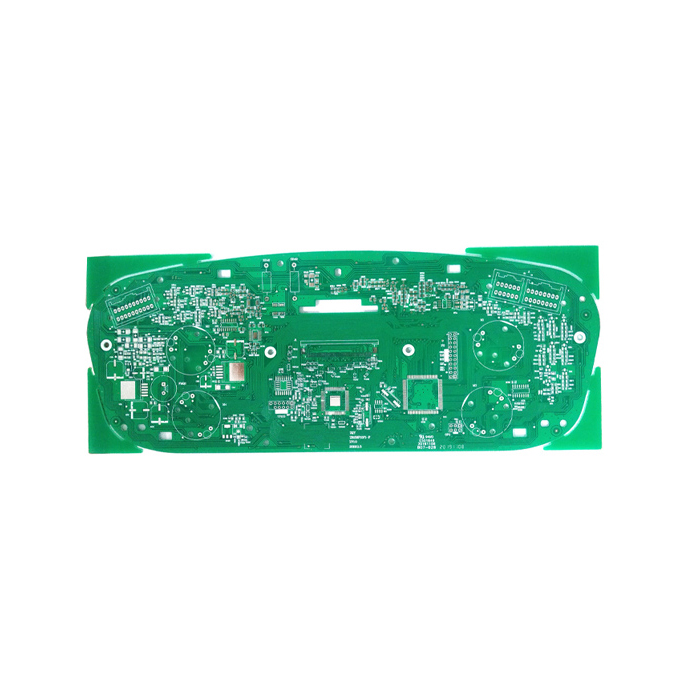

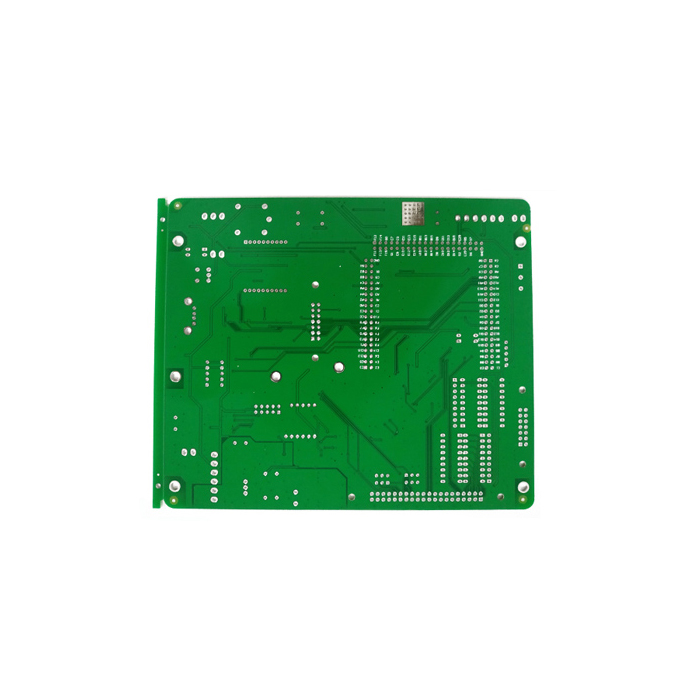

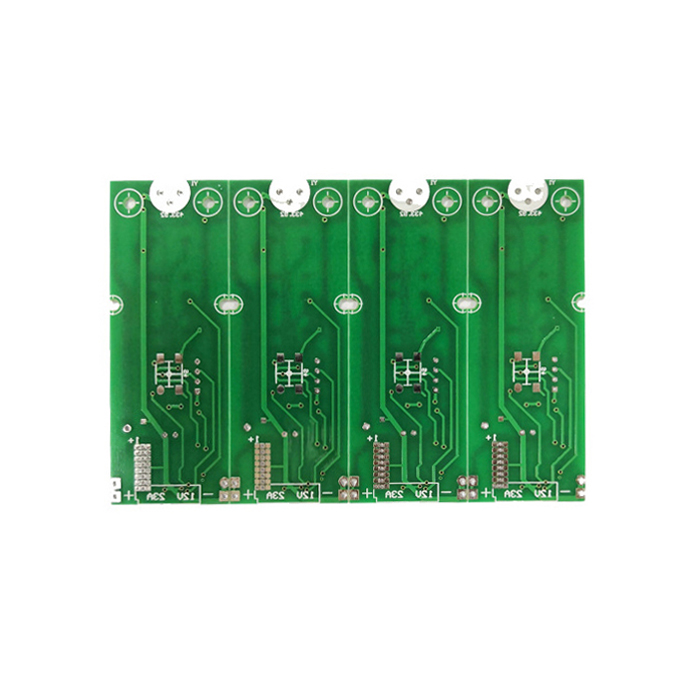

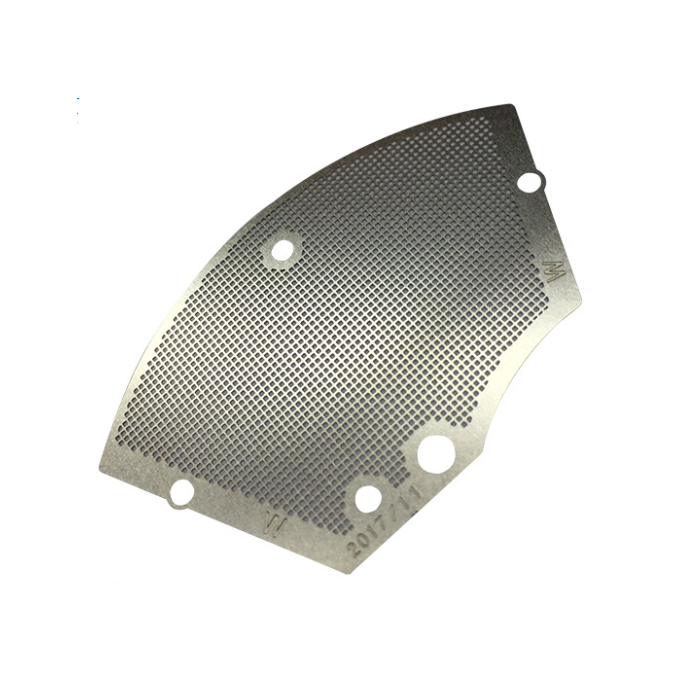

Metal Etching(Pcb Etching) Sample

What Can an Etching Machine Do in PCB Manufacturing?

Etching machines play a crucial role in the PCB manufacturing process by performing the etching operation, which involves the precise removal of unwanted copper from the surface of a printed circuit board (PCB) to create the desired circuit pattern. These machines utilize an etchant, typically an acidic solution, to selectively dissolve copper in specific areas. Let’s delve into the key functions and capabilities of etching machines:

1. Etching Copper: The primary function of an etching machine is to selectively eliminate the copper layer from the PCB substrate, leaving behind the desired circuit pattern. By utilizing a combination of chemical reactions and physical agitation, the machine effectively dissolves and washes away the undesired copper.

2. Circuit Pattern Formation: Etching machines enable the creation of intricate circuit patterns on the PCB. The process involves utilizing resist materials like photosensitive photoresist or protective tape to cover the areas that require protection from the etchant. By exposing the PCB to the etchant, the unprotected copper is removed, resulting in the formation of circuit traces, pads, and other essential conductive features.

3. Accuracy and Precision: Etching machines are designed to deliver precise and accurate etching results. They employ controlled spraying, dipping, or roller techniques to ensure even distribution and application of the etchant onto the PCB surface. This meticulous approach helps maintain the desired trace width, spacing, and overall circuit pattern quality.

4. Batch Processing: Efficiency is a key advantage of etching machines, as they can handle multiple PCBs simultaneously. Equipped with racks, conveyors, or trays, these machines enable the processing of several PCBs in a single batch. This capability facilitates efficient mass production of PCBs, saving valuable time and labor costs.

5. Etchant Recirculation and Filtration: Advanced etching machines often feature etchant recirculation and filtration systems. These systems contribute to the effectiveness and consistency of the etching process by removing debris and contaminants during operation. They also extend the life of the etchant, minimizing waste and associated costs.

6. Process Control and Monitoring: Modern etching machines are equipped with process control and monitoring systems. These systems enable precise regulation of essential etching parameters such as temperature, etchant flow rate, and agitation. Additionally, real-time monitoring and feedback mechanisms ensure consistent and reliable etching results.

It is worth noting that etching machines are specifically designed for the PCB manufacturing process and are not typically utilized for etching purposes in other materials or applications. Their primary function is the selective and precise removal of copper from the PCB surface to create the desired circuit pattern.

However, it is also important to mention that etching machines can handle other metals when necessary, expanding their versatility and applications.

Learn about the metals that can be processed by our etching machines

If you have any questions about etching machine or need assistance with your project, please do not hesitate to contact us.