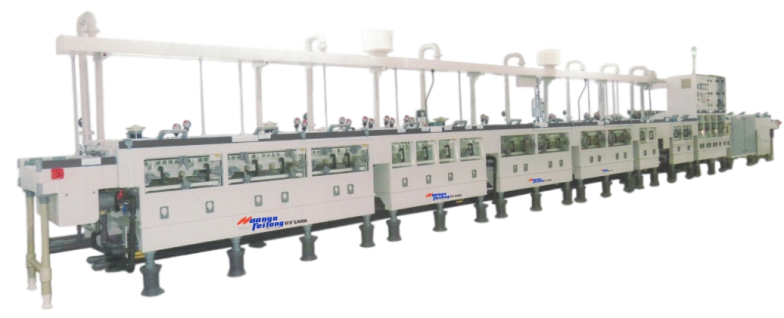

PCB Cleaning Machine Specification

Please note: There is no fixed size, speed or efficiency for the Dragon PCB Cleaning machine, this will need to be customised to suit your needs. The following parameters are for reference only.

|

Place of Origin

|

China

|

|

Guangdong

|

|

|

Brand Name

|

Dragon PCB Cleaning

|

|

Core Components

|

PLC, Gearbox, Gear

|

|

Key Selling Points

|

Low Maintenance Cost

|

|

Working width

|

500/600/700/800MM customized

|

|

Height

|

900-1100mm customized

|

|

Length

|

1m-100m depends on production

|

|

Voltage

|

380V/415V/440V customized

|

|

Material

|

PP 12/15/ 20MM

|

|

Electric unit

|

All CE marked

|

|

Heating type

|

SST316 titanium heater

|

|

Module metal

|

SST316 titanium material

|

|

Suitable for

|

High Precision PCB Cleaning

|

|

After Warranty Service

|

Video technical support, Online support, Spare parts

|

PCB (Printed Circuit Board) cleaning machine is a device designed to clean and remove contaminants from PCBs used in electronic devices. These machines are typically used in the manufacturing and repair processes of PCBs to ensure their reliability and performance. The principle of operation of a PCB cleaning machine involves several key components and processes.

- Cleaning Method: PCB cleaning machines use various methods to remove contaminants from the surface of the circuit boards. The common cleaning methods include:

- Spray Cleaning: In this method, cleaning solutions or solvents are sprayed onto the PCB surface using nozzles or jets. The contaminants are dissolved or loosened by the cleaning solution, and then the residues are rinsed off with water or other solvents.

- Ultrasonic Cleaning: This method involves immersing the PCB in a tank filled with a cleaning solution. Ultrasonic waves are then used to generate high-frequency vibrations that create microscopic bubbles in the solution. These bubbles implode near the PCB surface, producing a scrubbing action that helps dislodge and remove contaminants.

- Brush Cleaning: In this method, brushes or scrubbers are used to physically scrub the PCB surface. The brushes can be rotated or moved in a controlled manner to ensure even and effective cleaning.

- Cleaning Solutions: PCB cleaning machines use specialized cleaning solutions or solvents that are tailored to remove specific types of contaminants. These solutions are designed to be effective in removing flux residues, solder paste, oils, grease, dust, and other contaminants commonly found on PCBs. The choice of cleaning solution depends on the type and severity of the contaminants, as well as the PCB material and component sensitivity.

- Drying: After the cleaning process, the PCB needs to be thoroughly dried to prevent moisture-related issues. PCB cleaning machines often include a drying chamber or mechanism that utilizes heat, hot air, or a combination of both to evaporate any residual cleaning solution or moisture from the board. This ensures that the PCB is completely dry before it is further processed or assembled.

Precautions: While operating a PCB cleaning machine, certain precautions should be taken to ensure safety and maintain the integrity of the PCBs:

- Equipment and Operator Safety:

- Follow all safety guidelines and precautions provided by the manufacturer.

- Ensure that the cleaning machine is properly grounded to prevent electrical hazards.

- Use appropriate personal protective equipment (PPE) such as gloves and safety goggles to protect against chemicals and cleaning solutions.

- Compatibility:

- Ensure that the cleaning solution or solvent used is compatible with the PCB material, components, and any conformal coatings or protective layers.

- Avoid using cleaning solutions that may cause damage or corrosion to the PCB.

- Handling:

- Handle PCBs with care to avoid physical damage, bending, or scratching during the cleaning process.

- Ensure that the PCBs are properly secured or clamped to prevent movement or detachment during cleaning.

- Contamination Control:

- Maintain a clean environment around the PCB cleaning machine to prevent the introduction of additional contaminants.

- Regularly clean and maintain the machine, including filters and nozzles, to prevent the buildup of residues and ensure optimal cleaning performance.

- Operator Training:

- Provide adequate training to operators on the safe and proper use of the PCB cleaning machine.

- Educate operators about the potential hazards associated with cleaning solutions, solvents, and the handling of PCBs.

By adhering to these principles and precautions, PCB cleaning machines can effectively remove contaminants and ensure the cleanliness and reliability of printed circuit boards used in electronic devices.

If you have any questions about PCB Cleaning Machine with your project, please do not hesitate to contact us.