Printed Circuit Board (PCB) etching is a critical step in manufacturing, determining the precision and quality of the final product. To achieve high-yield production, optimizing etching machine parameters is essential. This guide explores key parameters that influence etch rate, resolution, and defect reduction.

Understanding Etching Rate vs. Resolution Trade-offs

The relationship between etch rate and resolution directly impacts trace width precision and undercutting. Higher etch rates can speed up production but may lead to excessive undercut, affecting circuit integrity.

| Etching Factor | Impact on Resolution | Recommended Action |

|---|---|---|

| Etchant Strength | High strength speeds etching but risks over-etching | Maintain optimal chemical balance |

| Etching Time | Shorter time minimizes undercut but requires strong control | Fine-tune based on material thickness |

| Board Material | Different materials react at varying speeds | Adjust process based on material properties |

Industry Insight: According to PCBWay, etching speed should be carefully balanced to avoid signal integrity issues in high-density interconnect (HDI) PCBs.

Temperature and Chemical Concentration Calibration

Maintaining the correct etchant temperature and chemical concentration ensures uniform etching results. The two most common etchants are ferric chloride (FeCl₃) and ammonium persulfate (NH₄)₂S₂O₈), each with distinct behaviors.

- Ferric Chloride (FeCl₃): High etching power, but prone to sludge formation.

- Ammonium Persulfate (NH₄)₂S₂O₈): Provides smoother etching but requires precise temperature control.

| Parameter | Ferric Chloride | Ammonium Persulfate |

|---|---|---|

| Optimal Temperature | 40-50°C | 50-60°C |

| Etch Rate Control | Moderate | More Sensitive |

| Common Issues | Residue Formation | Requires frequent concentration monitoring |

Best Practice: Regularly measure etchant concentration and refresh the solution to maintain efficiency.

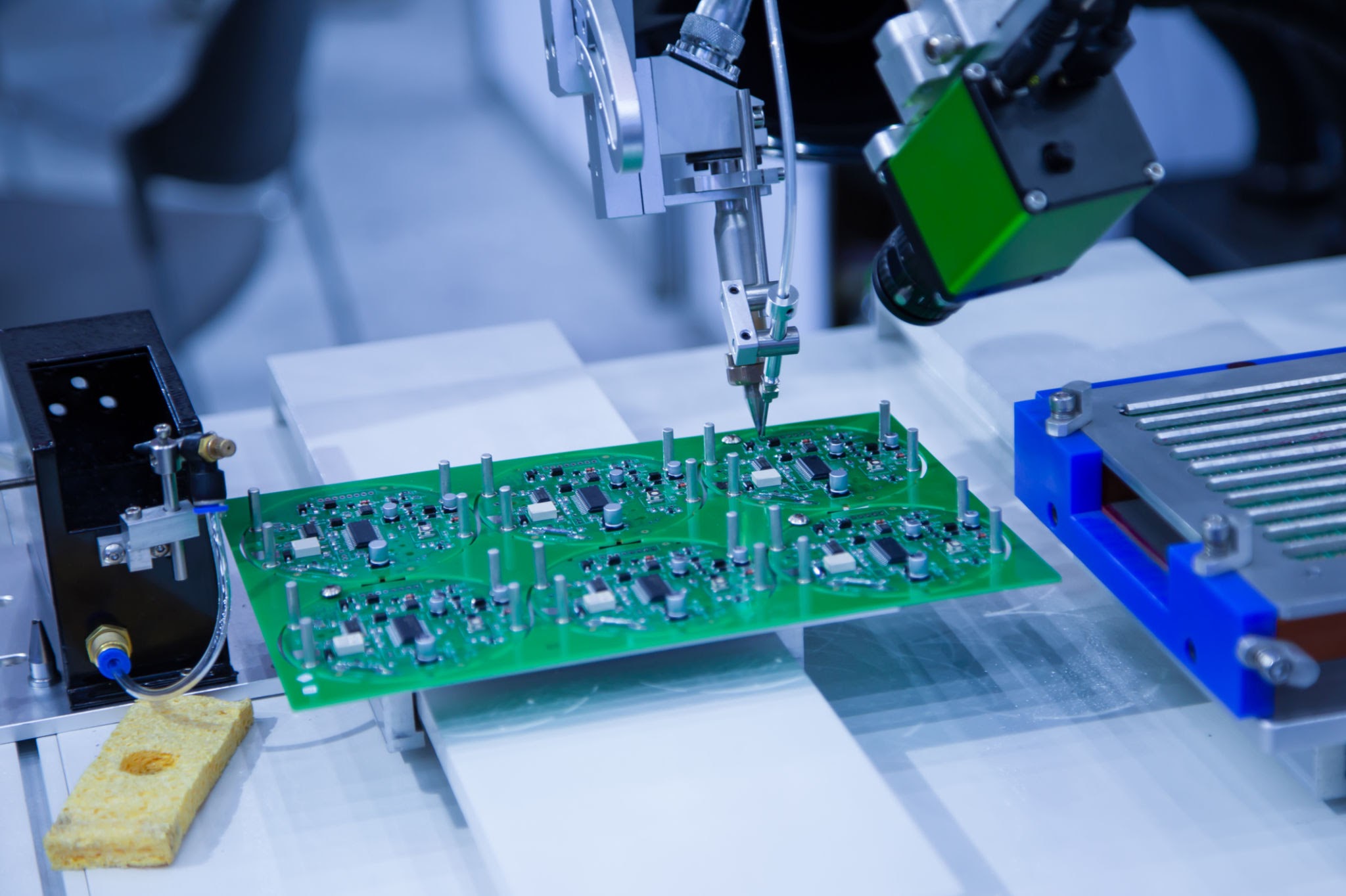

Nozzle Pressure Optimization for Uniform Etching

Spray etching machines use nozzle pressure to evenly distribute etchant, ensuring precise material removal. Pressure calibration is crucial for multilayer boards.

Key Considerations for Nozzle Optimization:

- Low pressure leads to uneven etching and defects.

- High pressure risks over-etching and material weakening.

- Optimal pressure ensures consistent removal rates and sharp trace edges.

| Nozzle Pressure | Impact on PCB |

|---|---|

| Too Low | Incomplete etching, residual copper |

| Too High | Excessive material loss, reduced yield |

| Optimized | Uniform traces, minimal defects |

Industry Example: AT&S, a leading PCB manufacturer, utilizes precision nozzle pressure control systems to achieve high-density PCB manufacturing with minimal defects.

Automated vs. Manual Parameter Adjustments

Modern closed-loop automation systems dynamically adjust etching parameters in real time, while traditional manual tuning relies on operator expertise.

| Method | Advantages | Challenges |

|---|---|---|

| Manual Tuning | Lower initial cost, flexibility | Inconsistent quality, operator-dependent |

| Automated System | Consistent etching, real-time adjustments | Higher setup cost, requires software integration |

Case Study: A comparison by Camtek source shows that automated etching systems improve process stability, especially in fine-pitch PCBs.

Troubleshooting Etching Defects (Over-Etching, Residual Copper)

Even with optimized parameters, etching defects can still occur. The table below outlines common defects and their fixes.

| Defect Type | Cause | Solution |

|---|---|---|

| Over-Etching | High chemical concentration or extended etching time | Reduce etchant strength, fine-tune exposure time |

| Undercutting | High etch rate or poor resist adhesion | Improve resist coating, optimize etch chemistry |

| Residual Copper | Low etchant efficiency or nozzle blockage | Regular maintenance, increase solution circulation |

Optimizing PCB etching machine parameters requires a fine balance between etch rate, resolution, and process automation. Leveraging automated controls, calibrated chemical solutions, and optimized nozzle pressure ensures high-yield production with minimal defects.