Dry film etching is a crucial step in the precision metal etching process, which is a highly precise and controlled technique for creating intricate patterns and features on thin metal sheets or foils. This process is often used in various industries, including electronics, aerospace, medical devices, and more, where precision and accuracy are paramount.

Here are some additional features and aspects to consider about dry film etching:

- High Precision and Accuracy:

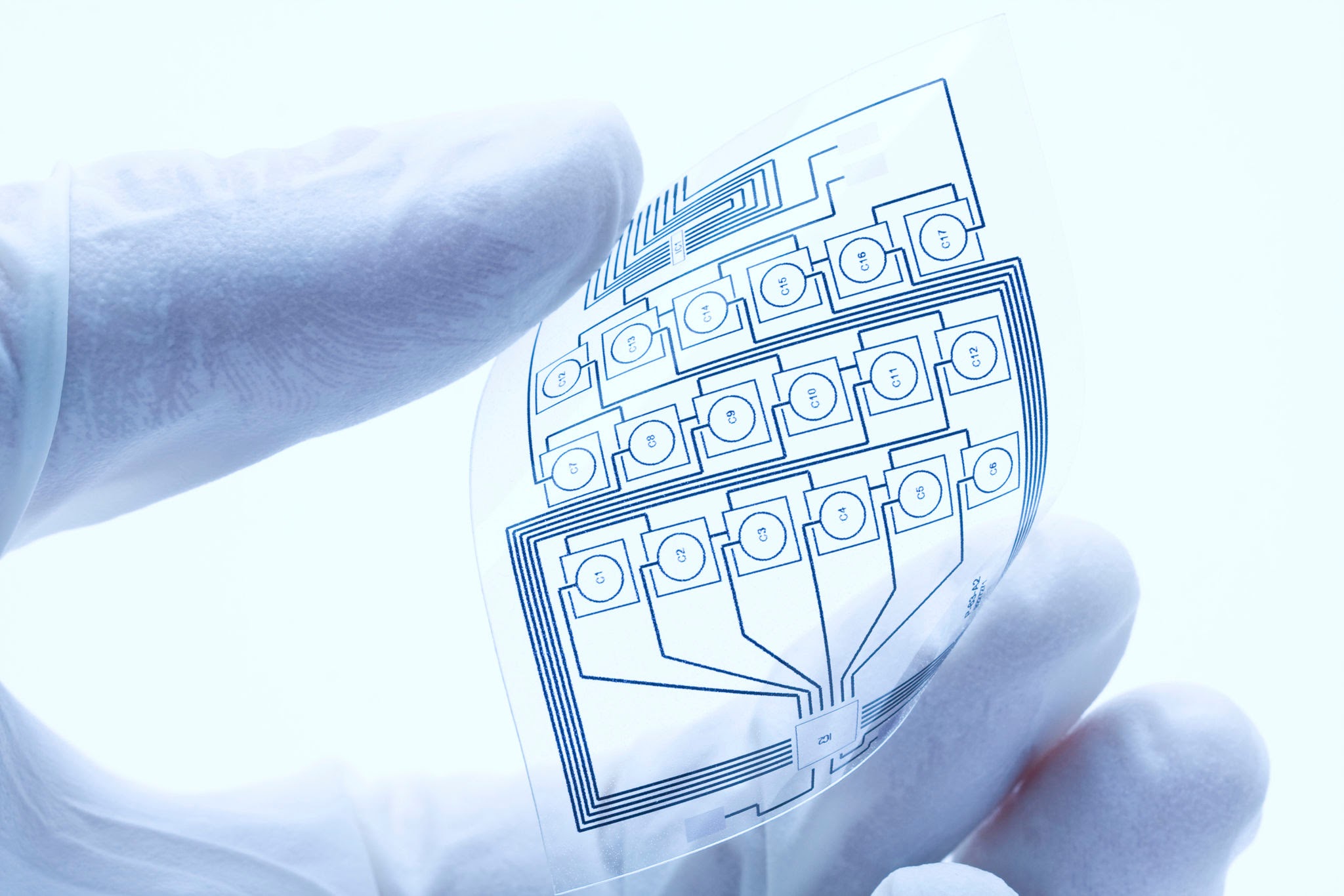

- Dry film etching is known for its exceptional precision and accuracy. It can create intricate and finely detailed patterns with tolerances as tight as a few micrometers. This level of precision is essential for manufacturing components used in electronics and other high-tech applications.

- Cost-Effective for Prototyping and Small Production Runs:

- Dry film etching is well-suited for prototyping and small production runs. Unlike some other manufacturing processes that require expensive tooling or molds, dry film etching is more cost-effective for producing small quantities of complex metal parts.

- Customization and Design Flexibility:

- Design changes can be implemented relatively easily in the dry film etching process. Since it involves exposing a resist to a mask, altering the mask design allows for rapid changes in the final etched pattern. This flexibility is advantageous when designing custom components.

- Material Compatibility:

- Dry film etching is compatible with various metals and alloys, including stainless steel, copper, aluminum, and more. This versatility allows manufacturers to choose the material that best suits the application’s requirements.

- No Tool Contact:

- Unlike some traditional machining processes that involve physical tooling, dry film etching is a non-contact method. This eliminates the risk of tool wear and damage to the substrate, making it ideal for delicate or thin materials.

- Minimal Heat Generation:

- Dry film etching is a cold-etching process, meaning it does not generate significant heat during the etching stage. This lack of thermal stress minimizes the risk of material distortion or warping, which is particularly important for thin metal foils.

- Burr-Free and Stress-Free Etching:

- The process produces burr-free edges and stress-free parts. This is crucial for components used in sensitive applications like microelectronics and medical devices, where sharp edges or residual stress can be problematic.

- Scalability:

- Dry film etching can be scaled up for larger production volumes when needed. This scalability makes it adaptable for both small-scale and large-scale manufacturing.

- Environmental Considerations:

- Dry film etching is generally considered to be a more environmentally friendly process compared to some other metal fabrication methods, as it does not produce large quantities of hazardous waste or emissions.

- Quality Control and Process Monitoring:

- Due to its precision, dry film etching allows for robust quality control and process monitoring. Manufacturers can closely monitor each step of the process to ensure that the final components meet the required specifications.

- Wide Range of Applications:

- Dry film etching is used in diverse industries, including electronics for printed circuit boards (PCBs), microelectromechanical systems (MEMS), sensors, medical devices, aerospace components, and more. Its versatility makes it applicable in various fields.

Overall, dry film etching is a highly specialized and valuable manufacturing process that excels in producing precise, intricate metal components while offering flexibility and cost-effectiveness for both small-scale and large-scale production.

Dry Film Metal Etching Equipment:

- Metal Cleaning Machine:

- Purpose: Used to clean the metal surface, removing contaminants to ensure proper adhesion of the dry film resist.

- Pressure Layer Machine:

- Purpose: Precisely applies the dry film resist onto the metal surface, ensuring uniform adhesion and thickness.

- Exposure Machine:

- Purpose: Exposes the dry film resist to UV light through a photomask, creating a pattern on the resist.

- Developer:

- Purpose: Contains a chemical solution that removes the unexposed portions of the dry film resist, revealing the metal surface beneath.

- Etching Machine:

- Purpose: Selectively removes metal from the exposed areas using chemical etching solutions, creating the desired pattern.

- Stripping Machine:

- Purpose: Removes any remaining dry film resist from the metal surface after etching.

Dry Film Metal Etching Workflow:

- Metal Cleaning:

- Clean the metal sheet or component to remove impurities and contaminants.

- Pressure Layer:

- Apply the dry film resist onto the cleaned metal surface using the pressure layer machine. Ensure uniform adhesion and thickness.

- Exposure:

- Place the metal with the dry film resist under the exposure machine.

- Expose the resist to UV light through a photomask that carries the desired pattern.

- Development:

- Transfer the exposed metal to the developer, which removes the unexposed resist, exposing the metal underneath.

- Etching:

- Immerse the metal into the chemical etching machine containing the etching solution. The chemical selectively removes the exposed metal areas, leaving the protected areas intact.

- Rinsing and Cleaning:

- Rinse the metal thoroughly to remove etching chemicals and residues.

- Stripping (if needed):

- Use stripping chemicals to remove any remaining masking material (resist) from the metal surface.

- Final Inspection:

- Inspect the etched metal for quality and accuracy.

If you are interested in finding out about Dry Film Metal Etching Equipment overall price. Please do not hesitate to contact us. Usually we will contact you within 2 days after we receive your information.