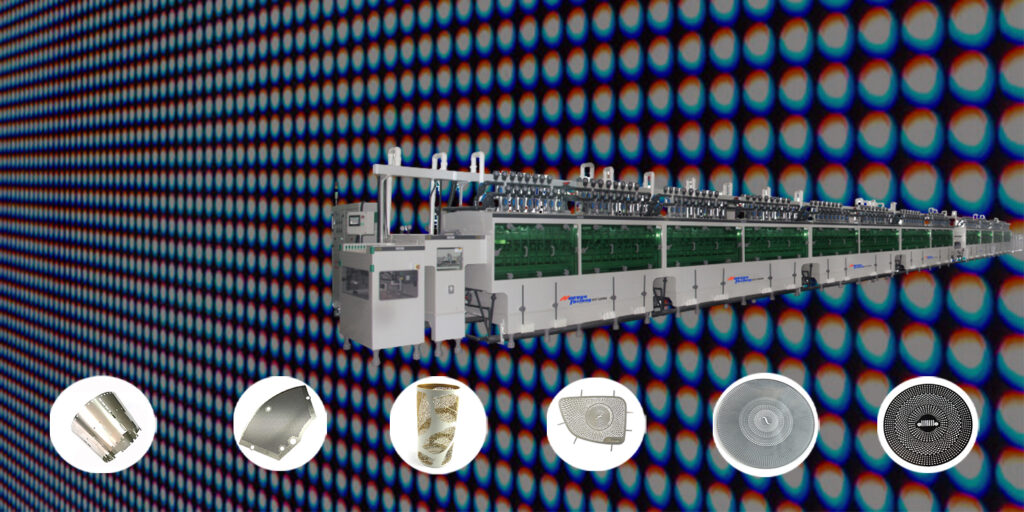

Electrochemical etching of stainless steel involves a precise and controlled process to achieve high-quality results. Below is an overview of the required equipment, estimated costs, and their specific purposes. The table also includes manufacturer information for reference.

Equipment Overview and Estimated Prices

| Equipment Name | Estimated Price | Purpose |

|---|---|---|

| Stainless steel electro Cleaning line | $4500/m | Cleans stainless steel using specific water quality standards. |

| Manufacturer: DragonEtching | dragonetching.com | |

| Stainless steel electro Painting and drying line | $4500/m | Applies and dries paint with precise temperature control. |

| Manufacturer: DragonEtching | dragonetching.com | |

| Exposure line | $18,000-$3,0000 | Uses LED or LDI for high-precision exposure. |

| Manufacturer: DragonEtching | dragonetching.com | |

| Developing line | $4500/m | Develops the exposed stainless steel accurately. |

| Manufacturer: DragonEtching | dragonetching.com | |

| Stainless steel electrochemical etching line | $4500/m | Performs the main etching process using copper chloride etchant. |

| Manufacturer: DragonEtching | dragonetching.com | |

| Stainless steel electro Stripping line | / | Strips away unwanted material post-etching. |

| Manufacturer: DragonEtching | dragonetching.com |

Detailed Steps of Stainless Steel Electrochemical Etching

Stainless Steel Electro Cleaning Line

- Process: Utilizes high-quality water to remove contaminants from stainless steel.

- Water Quality Recommendation: Use deionized water to prevent impurities.

Stainless Steel Electro Painting and Drying Line

- Temperature Control: Precise control is crucial for uniform paint application.

- Process Flow: Stainless steel is painted, then dried at controlled temperatures to ensure adhesion.

Exposure Line

- LED Exposure: Suitable for less complex patterns; works by exposing photoresist-coated stainless steel to UV light.

- LDI (Laser Direct Imaging): Ideal for high-precision patterns; uses laser beams for direct imaging.

- Work Flow:

- LED Exposure: Place the photoresist-coated steel under an LED light source.

- LDI Exposure: Use laser beams to expose the steel, adjusting parameters for pattern complexity.

Developing Line

- Post-Exposure: Develops the image after exposure by removing unexposed photoresist.

- Necessity: Developing reveals the pattern created during the exposure phase.

Stainless Steel Electrochemical Etching Line

- Process: Involves immersing the developed stainless steel into a copper chloride solution.

- Parameters:

- Temperature: Maintain between 40-50°C.

- Etchant Concentration: Typically 15-20% copper chloride.

- Experience Tips: Regularly monitor etchant strength and temperature for consistent results.

Stainless Steel Electro Stripping Line

- Details: Strips away residual photoresist and other unwanted materials post-etching.

- Procedure: Uses chemical baths or mechanical methods for cleaning.

Material and Etching Data Table

| Stainless Steel Series | Etching Temperature (°C) | Etchant Concentration (%) | Estimated Etching Depth (µm) | Etching Quality |

|---|---|---|---|---|

| 304 | 45 | 18 | 50 | High |

| 316 | 48 | 20 | 55 | Very High |

| 430 | 42 | 17 | 45 | Medium |

| 201 | 44 | 19 | 50 | High |

This detailed overview covers the key aspects and equipment necessary for stainless steel electrochemical etching. Following these guidelines ensures efficient and high-quality etching results. For further information and specific product details, please visit DragonEtching.