Learn about the benefits of using rigid flex PCBs, including their production process and use cases such as fingerprint technology. Discover top manufacturers and the equipment required for production.

igid-flex PCBs, also known as hybrid PCBs, are a combination of rigid and flexible circuit boards that are interconnected by plated through-holes. These circuit boards offer a variety of advantages over traditional PCBs, including increased reliability, reduced weight and space requirements, and enhanced design flexibility. In this article, we’ll explore the advantages of rigid-flex PCBs, their production process, and some of their common applications.

What is Rigid Flex PCB?

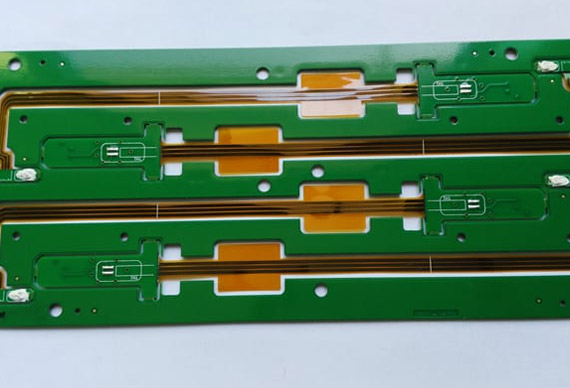

Rigid-flex PCBs are a type of printed circuit board that combines the characteristics of rigid and flexible circuits into a single design. These boards consist of multiple layers of flexible circuitry, which are laminated together with layers of rigid circuitry. The flexible sections of the board are typically used to connect components, while the rigid sections are used to mount components and provide mechanical stability.

Advantages of Rigid-Flex PCBs:

- Increased Reliability: The flexibility of these circuit boards makes them less susceptible to damage from mechanical stresses, vibration, and thermal expansion, which can improve their reliability.

- Reduced Weight and Space Requirements: The use of flexible circuitry can reduce the overall weight and size of the board, making them ideal for use in portable devices and other applications where space is limited.

- Enhanced Design Flexibility: The use of flexible circuitry also allows for more complex and intricate designs, which can improve performance and reduce manufacturing costs.

- Improved Signal Integrity: The use of flexible circuitry can reduce the number of interconnects required, which can improve signal integrity and reduce the potential for interference.

- Cost-Effective: Despite their many advantages, rigid-flex PCBs can be produced at a cost that is comparable to traditional PCBs, making them an attractive option for a wide range of applications.

Production Process of Rigid-Flex and Flexible PCBs:

The production process of rigid-flex PCBs involves several steps, including design, fabrication, and assembly. The design process typically involves the use of computer-aided design (CAD) software to create a 3D model of the board. This model is then used to generate the necessary manufacturing files, which are used to produce the board.

The fabrication process for rigid-flex PCBs involves a combination of flexible and rigid circuit board manufacturing techniques. The flexible circuitry is typically produced using a photo-etching process, while the rigid circuitry is produced using a subtractive or additive process.

Once the circuit boards have been produced, they are assembled together using plated through-holes, which are used to create electrical connections between the different layers of the board. The assembly process also involves the placement of components, which are then soldered onto the board.

Use of Fingerprint Rigid-Flex PCB:

One of the most common applications of rigid-flex PCBs is in fingerprint sensors. These sensors require a high degree of flexibility, which can be achieved using flexible circuitry. The rigid sections of the board are used to mount the sensor components and provide mechanical stability.

Cost:

The cost of producing rigid-flex PCBs can vary depending on the complexity of the design, the number of layers, and the volume of the order. However, rigid-flex PCBs are typically more expensive than traditional PCBs due to the additional manufacturing steps and materials required.

Famous Manufacturers:

Some of the well-known manufacturers of rigid-flex PCBs include:

Equipment Required for Production:

The production of rigid-flex PCBs requires several specialized pieces of equipment, including:

- Etching machine: This machine is used to remove unwanted copper from the surface of the PCB using a chemical solution. It typically consists of a tank filled with the etchant solution, and a mechanism for moving the PCB through the solution.

- Plating machine: This machine is used to add a layer of metal to the surface of the PCB in order to enhance its electrical conductivity and protect it from corrosion. It typically consists of an electroplating bath containing a solution of metal ions, and a mechanism for applying an electric current to the PCB.

- Photoresist equipment: This equipment is used to apply the photoresist material to the surface of the PCB, and to expose it to UV light in order to selectively harden the photoresist in the areas where the copper is to be retained.

- Clean room facilities: Clean rooms are used to prevent contamination of the PCB during production, and to ensure that the final product meets the required quality standards. Clean rooms typically have controlled air flow, humidity, and temperature, and are equipped with specialized equipment for handling and assembling PCBs.

- Testing and inspection equipment: Once the PCB has been produced, it must be tested and inspected to ensure that it meets the required quality standards. This typically involves using specialized equipment to test the electrical conductivity and other properties of the PCB, and to inspect it for defects and other issues.