Chemical etching is a powerful and cost-effective method for creating detailed and precise metal parts, widely used in various industries. Whether it’s for common metals like copper, iron, aluminum, stainless steel, titanium, or for PCB manufacturing, chemical etching offers distinct advantages over alternative methods like laser cutting, CNC grinding, and CNC turning. In this article, we’ll explore the benefits of chemical etching, particularly focusing on its cost efficiency and versatility, and discuss the crucial role of chemical etching machines.

Precision and Detail in Everyday Products

Chemical etching shines when it comes to producing fine details in metals, making it ideal for a wide range of applications from everyday products to high-tech components.

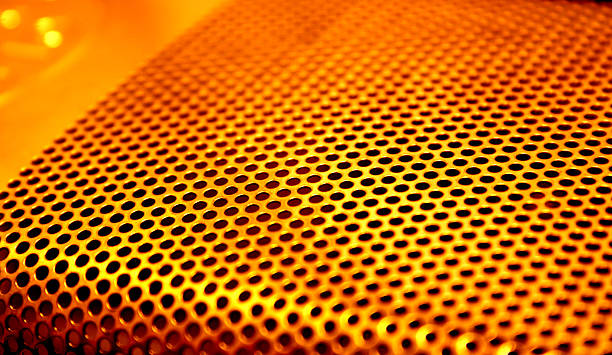

- Stainless Steel Filters: Stainless steel is favored for its durability and corrosion resistance, making it a popular choice for filters in various applications. Chemical etching allows for the creation of precise openings in these filters without compromising the strength of the material, ensuring high performance and longevity.

- Copper Nameplates: Copper is widely used for nameplates and signage due to its aesthetic appeal and durability. The precision of chemical etching ensures that even the most intricate designs are accurately reproduced, offering a superior finish compared to other methods.

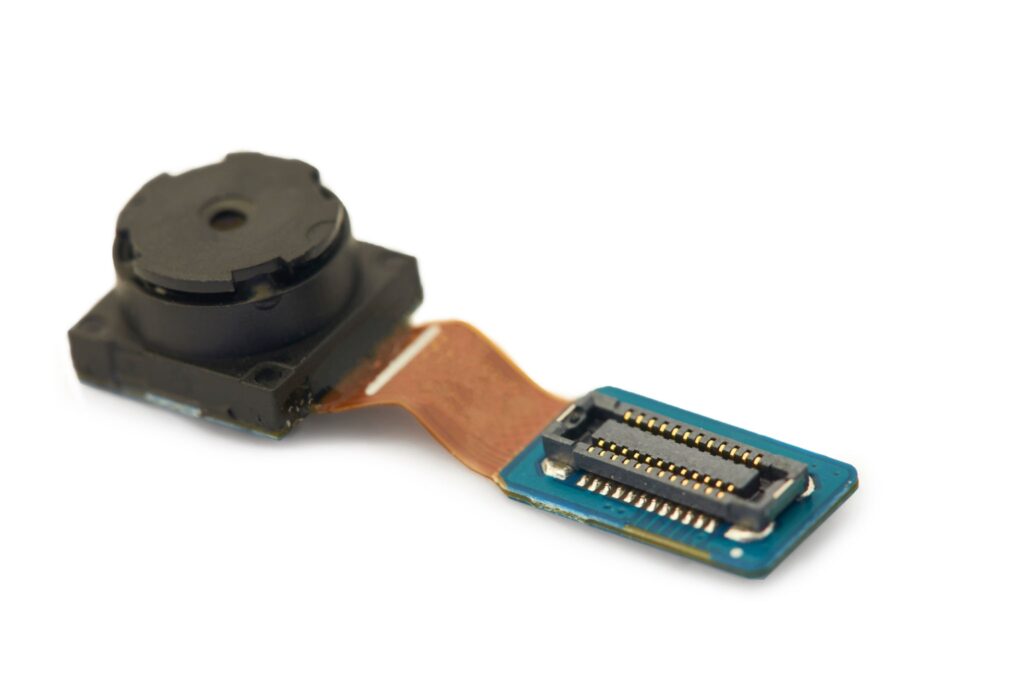

- Titanium and Aluminum Precision Parts: For industries like aerospace and medical devices, where precision is paramount, chemical etching is the preferred method for creating complex parts from titanium and aluminum. These metals are difficult to machine using traditional methods, but chemical etching can achieve the desired accuracy without introducing stress or altering the material’s properties.

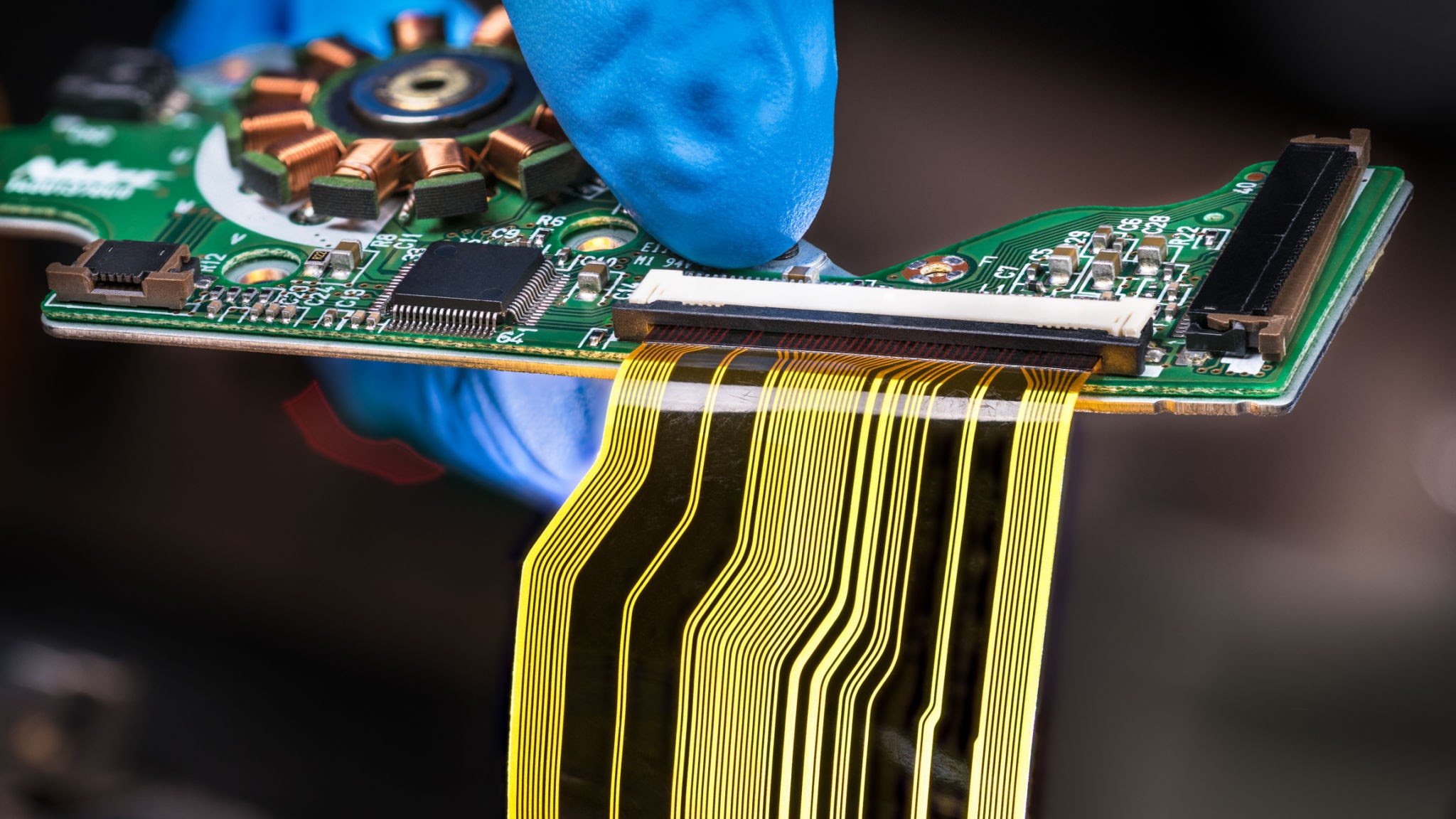

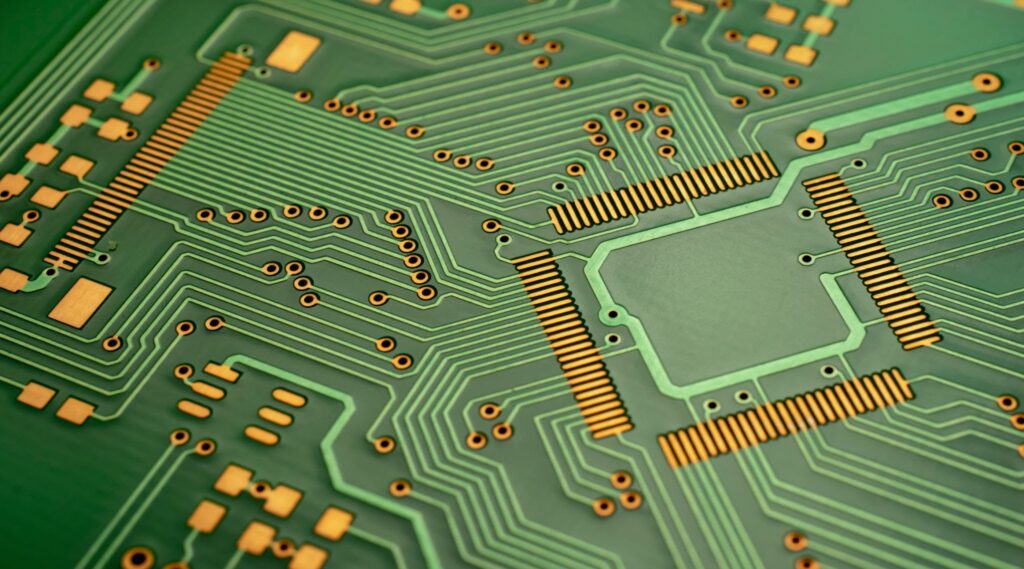

PCB Manufacturing: The Backbone of Modern Electronics

Printed Circuit Boards (PCBs) are critical components in all electronic devices, and chemical etching is a key process in their production. By precisely removing unwanted copper, chemical etching creates the intricate circuit patterns necessary for PCB functionality. While laser cutting and CNC machining are alternatives, they often fall short in terms of cost efficiency and the ability to produce highly detailed designs on a large scale.

Why Chemical Etching Outperforms Laser Cutting and CNC Machining

When it comes to manufacturing precision parts, chemical etching offers several advantages over laser cutting and CNC machining:

- Superior Precision: Chemical etching allows for the creation of extremely fine details, which can be challenging to achieve with laser cutting or CNC machining. This is particularly important in industries where precision is critical, such as electronics and medical devices.

- Material Integrity: Unlike laser cutting, which can introduce heat-affected zones, or CNC machining, which can cause stress and deformation, chemical etching is a non-contact process. This ensures that the material’s original properties are preserved, resulting in a higher quality end product.

- Cost Efficiency: Chemical etching is often more economical than laser cutting or CNC machining, especially for high-volume production. The lower setup costs and ability to scale the process make it an attractive option for both large and small-scale projects.

- Versatility: From thin foils to thicker sheets, chemical etching can handle a wide range of materials and thicknesses, making it suitable for diverse applications across various industries.

The Importance of Chemical Etching Machines

Central to the chemical etching process are specialized machines designed to handle the precise and controlled removal of material. These machines ensure consistency, accuracy, and efficiency, making them indispensable in the production of high-quality etched parts. Whether for PCBs, filters, or intricate metal components, chemical etching machines play a crucial role in modern manufacturing.

Conclusion

Chemical etching is the ideal solution for producing detailed, precise, and cost-effective metal parts. Whether working with copper, iron, aluminum, stainless steel, titanium, or PCBs, chemical etching offers unmatched advantages over laser cutting and CNC machining. As industries continue to demand higher precision and efficiency, chemical etching and the machines that enable it will remain at the forefront of manufacturing innovation.