Acid etching, also known as photo etching, chemical etching or chemical milling, is a sheet metalworking technology which uses acid etchants to machine complex, highly accurate precision metal components.

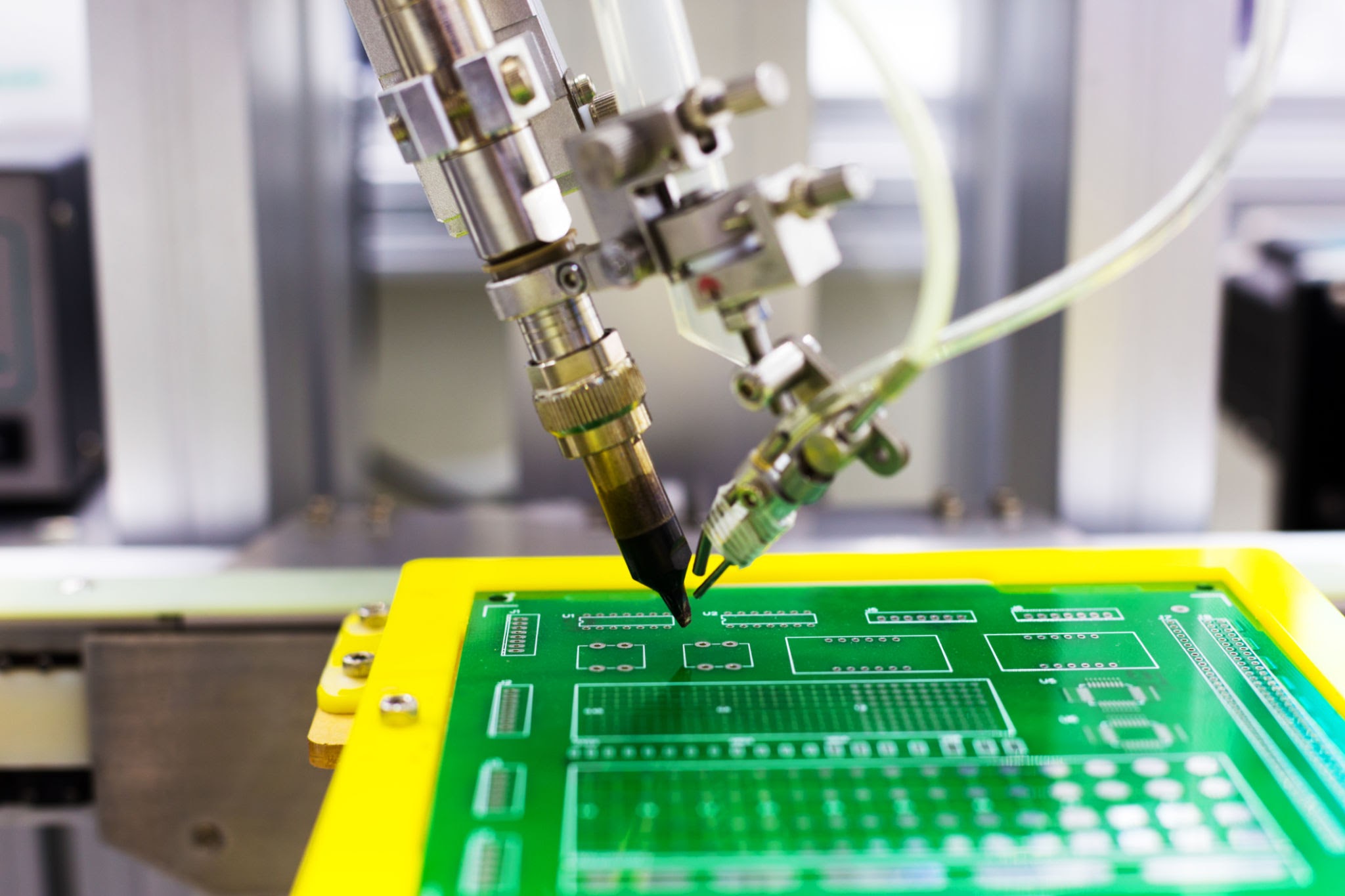

Acid etching machines are used to remove material from metal parts using acid. The process involves the following steps:

- Preparation: The metal part is cleaned thoroughly to remove any dirt, grease, or contaminants from the surface. This is important to ensure proper adhesion of the acid and uniform results.

- Masking: Areas that should be protected from the acid are covered using a mask or a resist material. This could be done by applying a special adhesive film or using a resist pen to draw the desired pattern on the part.

- Acid application: The prepared metal part is then placed in the acid etching machine. The machine consists of a tank filled with a suitable acid solution such as ferric chloride or hydrochloric acid. The part is submerged in the acid solution, and the time and temperature are controlled depending on the desired depth and speed of etching.

- Etching process: The acid dissolves the exposed metal surface, creating a recessed pattern or design. The depth and quality of the etch can be controlled by adjusting the time, temperature, and concentration of the acid solution.

- Rinsing and neutralizing: Once the desired etching is achieved, the metal part is removed from the acid solution and thoroughly rinsed with water to remove any residual acid. It is then neutralized using a neutralizing agent to stop the etching process and prevent further reaction with the metal.

- Finishing: After the etching process, the resist material is removed, and the metal part is cleaned, dried, and polished if necessary. This reveals the etched pattern or design on the metal surface.

It is important to follow safety procedures and use appropriate protective equipment when working with acid

What does owning an acid etching machine do?

Owning an acid etching machine allows you to perform acid etching processes on metal parts at your own facility. This offers several benefits:

- Customization: With an acid etching machine, you have the freedom to customize metal parts according to your specific requirements. You can etch intricate designs, logos, serial numbers, or any desired patterns onto the metal surface. This allows for personalization and branding opportunities.

- Prototyping and product development: Acid etching machines enable you to quickly and efficiently create prototypes or test different designs on metal parts. This helps in the product development process by allowing you to evaluate aesthetics, functionality, and fit before committing to large-scale production.

- Production control: Owning an acid etching machine gives you control over the production process. You can etch metal parts in-house, ensuring quality control, shorter lead times, and reduced dependency on external suppliers. This can be particularly useful for businesses that require custom or small-batch production.

- Cost savings: By owning an acid etching machine, you can eliminate the need for outsourcing etching services, which can be costly and time-consuming. In the long run, this can lead to cost savings and improved efficiency.

- Versatility: Acid etching machines can be used on a wide range of metals, including stainless steel, aluminum, brass, copper, and more. This versatility allows you to work with different materials and expand your applications.

However, it is important to note that owning an acid etching machine also requires proper knowledge, training, and adherence to safety guidelines to ensure the safe handling and disposal of acids involved in the process.

What metals can an acid etcher etch?

- Stainless steel: Acid etching can be used to create intricate designs, patterns, logos, or text on stainless steel surfaces, commonly used in the fabrication of kitchen appliances, automotive parts, and architecture.

- Aluminum: Acid etching can be applied to aluminum surfaces to etch designs, text, or even photographs. It is commonly used in industries such as aerospace, signage, and decorative applications.

- Brass: Brass can be etched using acid to create decorative patterns, logos, or designs. Acid etching on brass is often used in jewelry, nameplates, or decorative items.

- Copper: Acid etching can be used on copper surfaces to create artistic designs, engravings, or patterns. It is commonly employed in the production of artworks, sculptures, and electrical components.

- Nickel: Acid etching can be employed on nickel surfaces for various purposes, such as decorative elements, prototypes, or to create specific surface textures.

- Zinc: Acid etching can be used on zinc surfaces to create intricate designs, textures, or patterns. It is often employed in architectural applications and the production of decorative items.

See all the metals our acid etchers can etch!

- Aluminum

- Beryllium Copper

- Brass

- Bronze

- Copper

- Copper-Nickel

- Elgiloy

- Havar

- Inconel

- Invar

- Kovar

- Metglas

- Molybdenum

- Monel

- Mu-Metal

- Nickel

- Nickel silver

- Nickel-iron

- Phosphor bronze

- Spring steel

- Stainless Steel

- Steel

- Titanium

- Tungsten

- Tungsten-Copper (W-Cu)

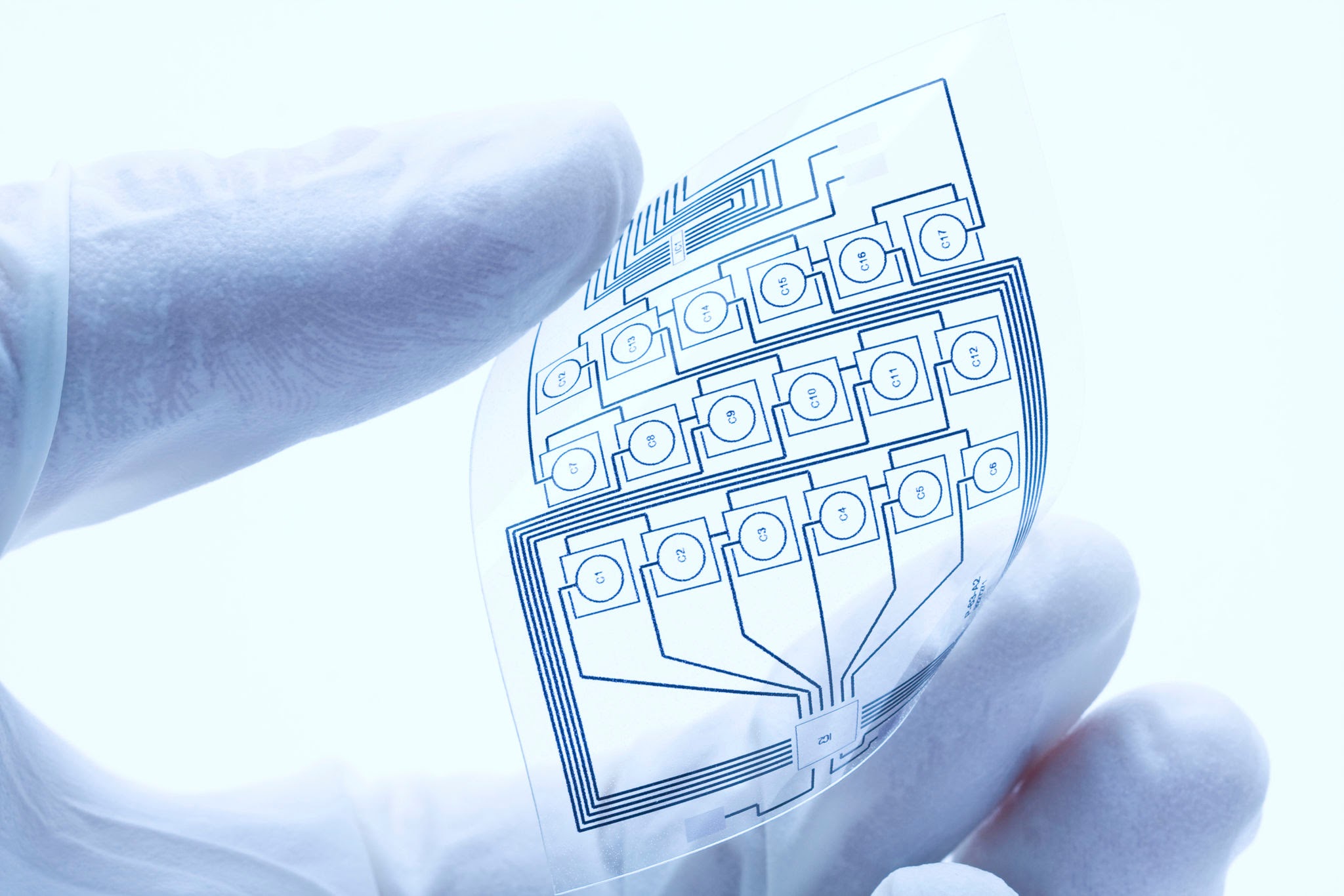

What do I need to know about acid-etched metal design?

- Assumptions Matter: Before delving into the design criteria, it’s crucial to set the right assumptions. For instance, in the case of wet etching, we assume a specific thickness. For the purpose of this discussion, let’s consider a thickness ranging from 0.1mm.

- Etching design formulas versus material thickness: Assuming a material thickness of 0.1mm, one of the first design criteria to consider is the hole diameter. To ensure proper etching, it’s often recommended to make the hole slightly larger than the material thickness. In this case, 1.2 times the material thickness would be 0.1mm * 1.2 = 0.12mm. Therefore, if the material thickness is 0.1mm, the hole should be designed to have a diameter of at least 0.12mm.

- Material Choice: The choice of material plays a significant role in wet etching. Different materials react differently to etchants. Engineers must select materials that are compatible with the chosen etchant to ensure a successful process.

- Hole Size Matters: The size of the holes created during wet etching is a critical design criterion. Smaller holes may lead to incomplete material removal, while larger holes may compromise structural integrity. Typically, materials with a thickness of 100μm or less can accommodate holes with a diameter of 0.12mm or more. Larger holes often result in more aesthetically pleasing and structurally sound outcomes.

- Alignment and Precision: Achieving precise alignment of the etched features is vital. Design drawings should incorporate alignment markers or registration features to ensure accurate positioning during the etching process. This is particularly crucial when dealing with multilayer structures or when specific patterns must be aligned with pre-existing features.

- Minimum Feature Size: It’s advisable to establish a minimum feature size for your design drawings. For instance, it’s generally recommended that no marked details be smaller than 0.1mm. This corresponds to 100μm. Maintaining a minimum feature size helps ensure that the etching process can accurately replicate the desired patterns and structures without the risk of incomplete or distorted etching.

- Quality Control and Inspection: Design criteria should include provisions for quality control and inspection during and after the wet etching process. This involves specifying methods and tools for verifying that the final product meets the intended design specifications. Inspection processes may include optical microscopy, surface profilometry, or other measurement techniques to validate critical dimensions and surface finish.

Customize Your Acid Etcher from Dragon Etching