Spray vs. Immersion Systems: Pros and Cons

Spray systems and immersion systems are the two primary types of chemical etching machines used in PCB production. Each has its own set of advantages, depending on the complexity of the design, required speed, and precision.

| Factor | Spray System | Immersion System |

|---|---|---|

| Etching Speed | Faster due to efficient liquid flow | Slower but more consistent over larger surfaces |

| Uniformity | More uniform for smaller, complex designs | Less uniform, can be affected by agitation and time |

| Material Compatibility | Best for fine-line, high-density designs | Suitable for thicker substrates, multi-layer PCBs |

| Cost | Higher initial investment, more maintenance | Lower initial cost, easier maintenance |

Etchant Chemistry: Ferric Chloride, Ammonium Persulfate

Chemical etchants are key in achieving precise and clean PCB etching. Commonly used etchants include Ferric Chloride and Ammonium Persulfate.

- Ferric Chloride: Typically used for single-sided PCBs, offering good control over the etching process but requires precise temperature regulation.

- Ammonium Persulfate: Ideal for more complex, high-precision designs like HDI PCBs. It’s gentler on copper surfaces and yields sharper etching lines.

Temperature and Pressure Control Mechanisms

Maintaining optimal temperature and pressure is crucial for achieving high-quality etching results.

- Temperature: Generally maintained between 40°C to 50°C to ensure consistent etching and to avoid over-etching.

- Pressure: Adjusted to maintain even chemical distribution during the etching process, particularly in spray systems.

Optimizing Etching Speed and Uniformity

The etching speed and uniformity are key factors in precision PCB manufacturing. Speed is controlled by adjusting:

- Etching solution concentration

- Temperature and pressure

- Substrate type and thickness

Uniformity is ensured by maintaining consistent flow rates in spray systems or the immersion depth in immersion systems.

Nozzle Design for Consistent Spray Patterns

In spray systems, nozzle design plays a critical role in ensuring uniform spray patterns. Optimal nozzles distribute etchant evenly across the surface to minimize uneven etching and defects.

Real-Time Monitoring with IoT Sensors

Modern chemical etching machines are increasingly incorporating IoT sensors for real-time monitoring. These sensors track variables such as temperature, pressure, and etchant concentration, providing instant feedback and facilitating immediate adjustments.

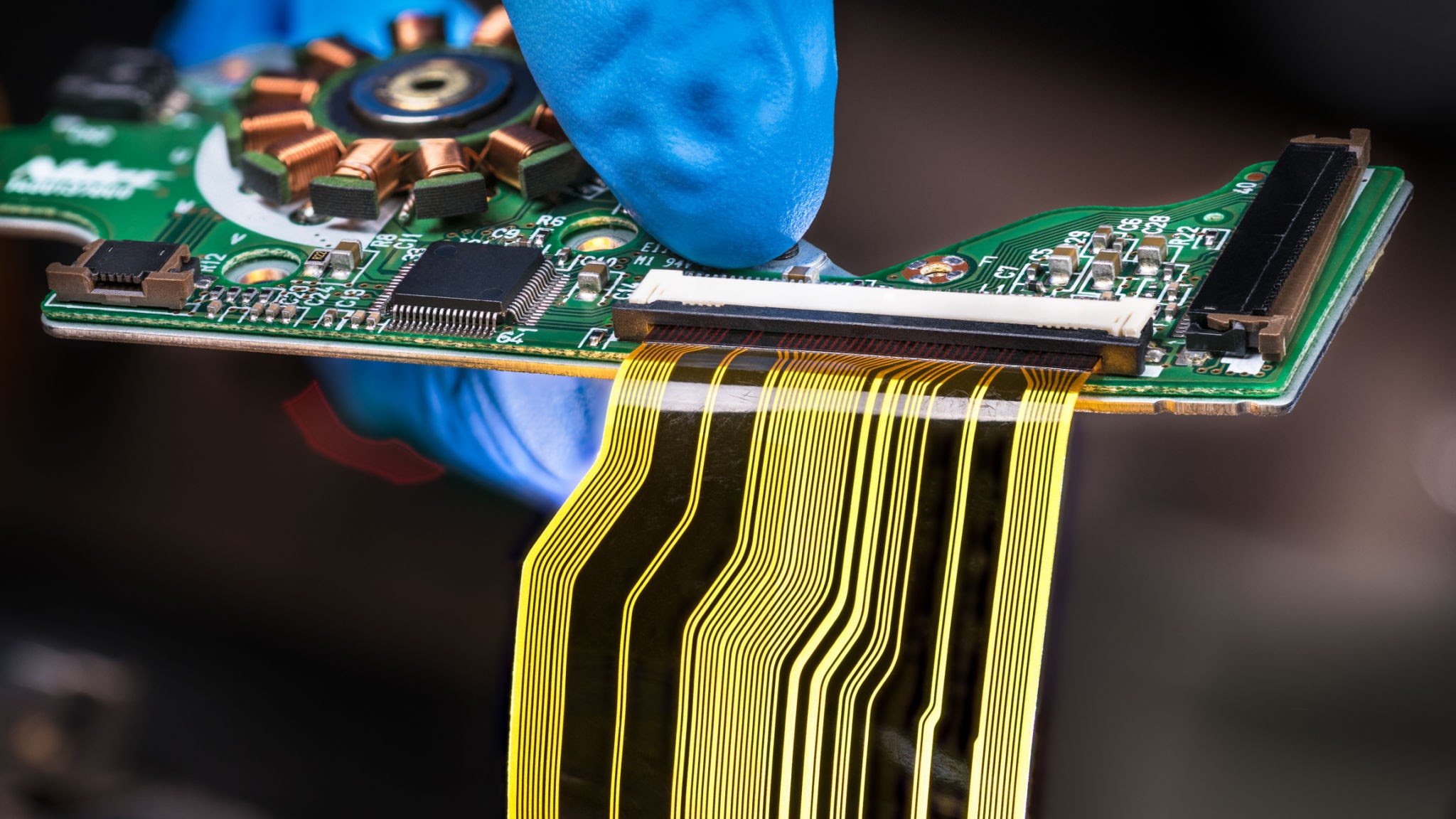

Material Compatibility for Multilayer PCBs

For multilayer PCBs, it’s important that etching machines handle various materials like Copper, FR-4, and high-frequency substrates. The etching system must be material-specific to ensure accurate and clean etching, especially when dealing with sensitive materials.

Handling Copper, FR-4, and High-Frequency Substrates

- Copper: Requires etchants that offer precise control to avoid damaging traces.

- FR-4: A common PCB material that needs precise etching to preserve structural integrity.

- High-Frequency Substrates: These materials require specialized etching systems to maintain signal integrity and minimize losses.

Etch Factor Control for Fine Traces (<3 mil)

For fine traces (<3 mil), etch factor control is essential. The etch factor determines the width-to-depth ratio of the etch and is crucial for creating high-precision circuits. Close monitoring and adjustments to etching time, solution concentration, and temperature help maintain optimal etch factor values.

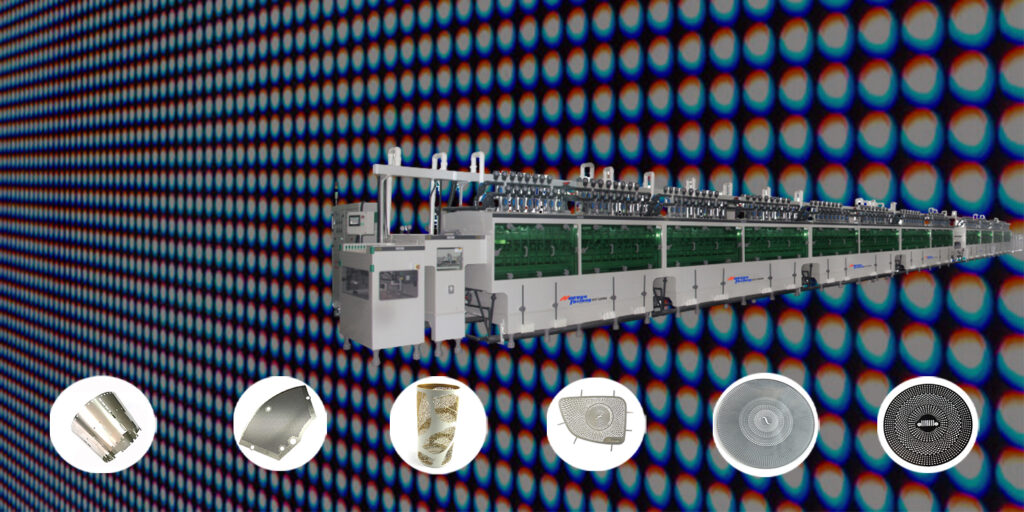

Integration with Other Wet Processing Equipment

Chemical etching machines are typically integrated with other wet processing equipment in a PCB manufacturing line, such as cleaning lines (acid/alkaline) and plating systems. This integration ensures that the PCB is thoroughly cleaned and plated after etching, resulting in a finished product with high electrical performance and structural integrity.

| Wet Processing Equipment | Function |

|---|---|

| Cleaning Lines (Acid/Alkaline) | Removes residual etchant and prepares the board for plating |

| Plating / PTH Systems | Deposits metal layers onto the PCB after etching |

Case Study: High-Density Interconnect (HDI) PCB Production

HDI PCBs are particularly challenging to manufacture due to their small traces and fine vias. A case study focusing on the production of 20μm line width PCBs demonstrates the precision of chemical etching machines in creating high-density interconnects with remarkable accuracy.

Example: A leading PCB manufacturer used Ammonium Persulfate etching to produce HDI PCBs with line widths under 20μm, significantly improving their electrical performance and signal integrity.