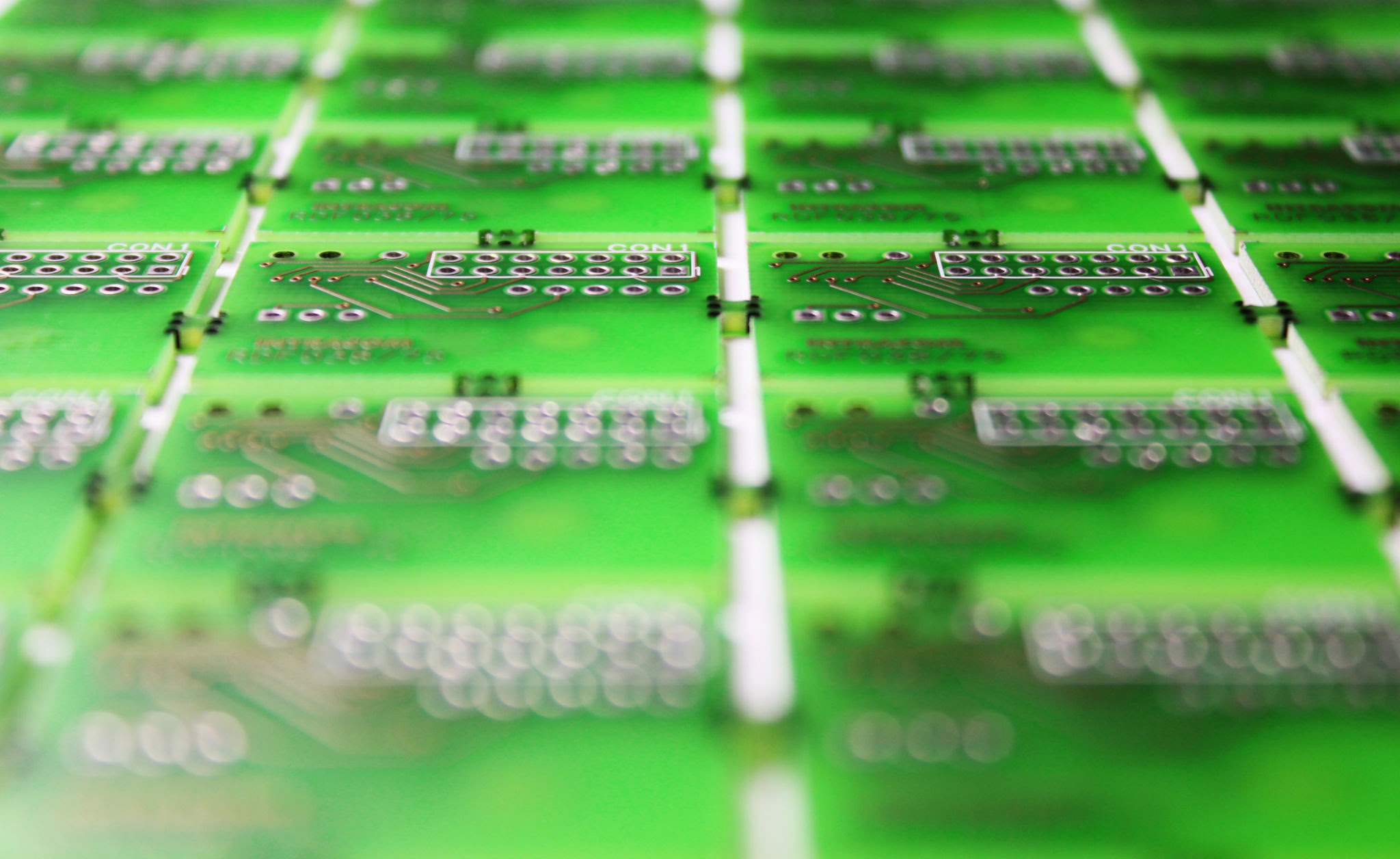

Equip your facility with the comprehensive PCB manufacturing equipment needed to produce single-sided, double-sided, multilayer, and rigid-flex PCBs efficiently. Streamline your production process with the right tools. Get started today!

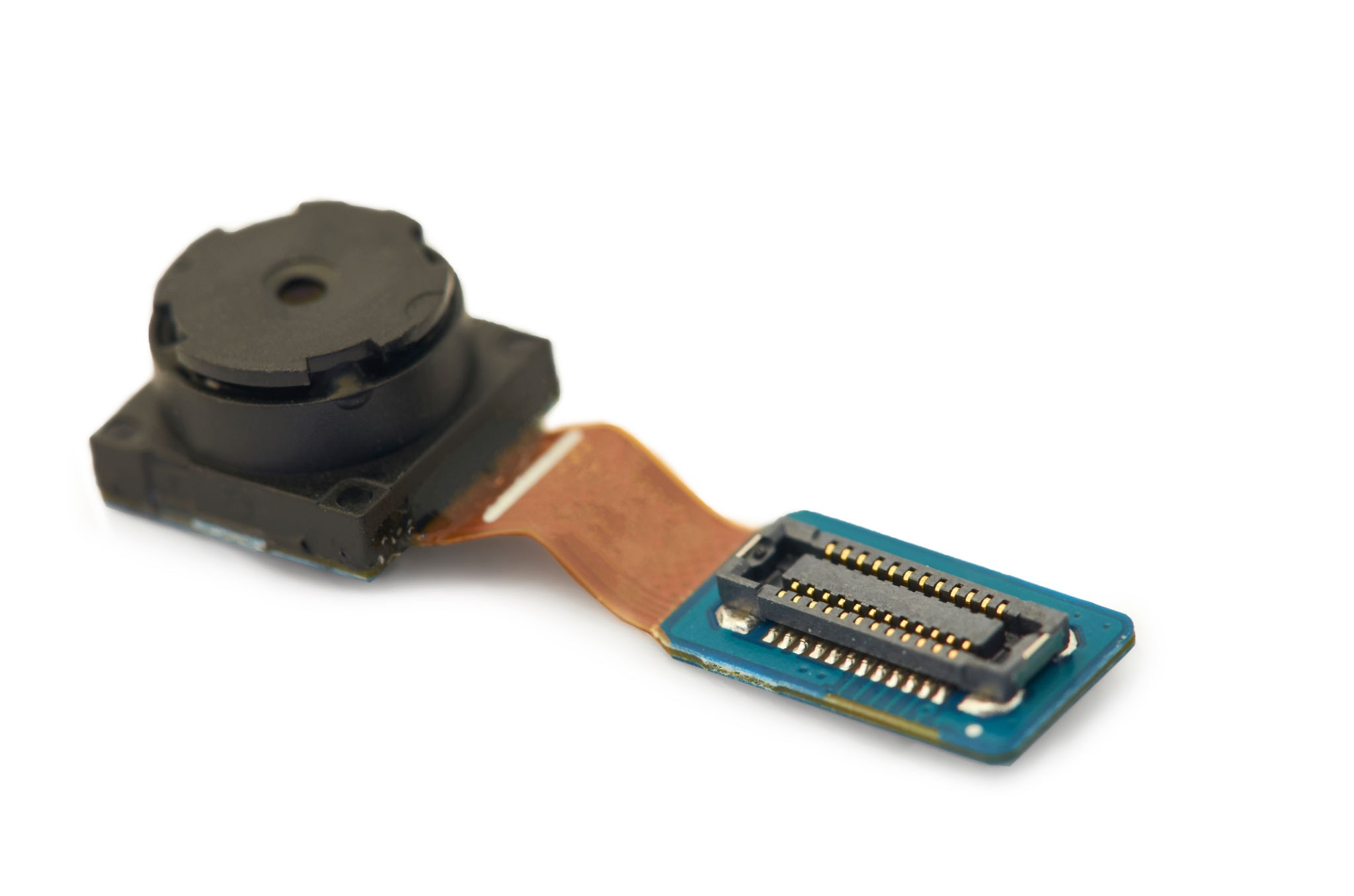

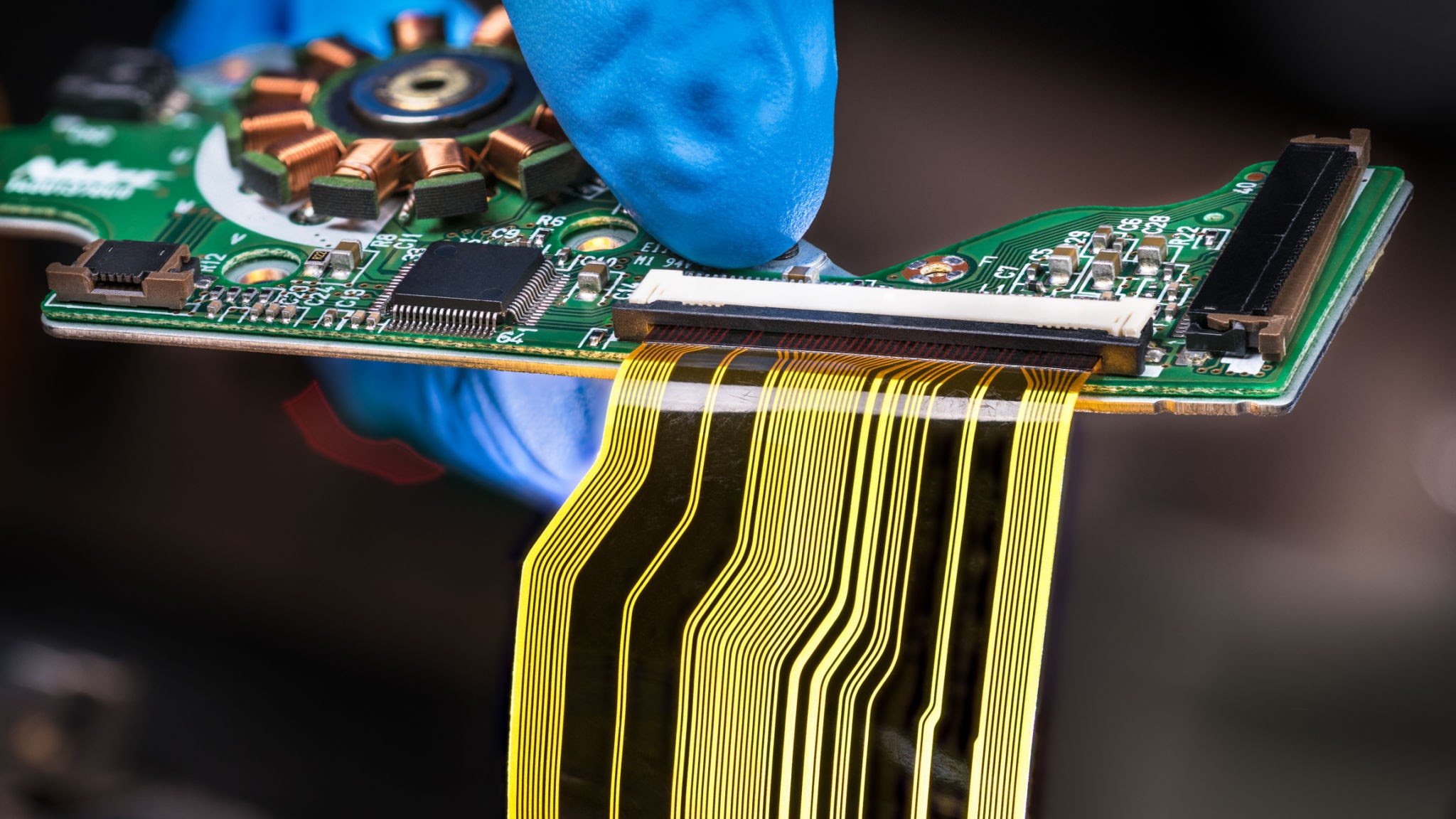

Single-Sided FPCB, Double-sided FPCB, Multilayer FPCB, and Rigid-Flex FPCB

To manufacture different types of flexible printed circuit boards (FPCBs), various equipment and processes are involved. Here’s a general overview of the equipment typically used for manufacturing single-sided FPCBs, double-sided FPCBs, multilayer FPCBs, and rigid-flex FPCBs:

- Single-Sided FPCB:

- Substrate Cutting Machine: Used to cut the flexible substrate (usually polyimide or polyester) into desired shapes and sizes.

- Imaging/Exposure Equipment: Used to transfer the circuit pattern onto the substrate through a photosensitive film or dry film resist.

- Etching Machine: Used to chemically remove unwanted copper from the substrate, leaving behind the desired circuit pattern.

- Plating Equipment: Used for copper electroplating to enhance the copper thickness and ensure good conductivity.

- Solder Mask Coating Machine: Used to apply a protective solder mask layer over the copper traces, leaving only the desired areas exposed for soldering.

- Surface Finishing Equipment: Used for applying a final finish to the exposed copper surfaces, such as hot air leveling (HASL), immersion gold, or immersion tin.

- Double-Sided FPCB:

- Same equipment as for single-sided FPCBs, with the addition of the following:

- Drilling Machine: Used to drill holes for component leads and vias to establish electrical connections between the two sides of the board.

- Electroless Copper Deposition System: Used for depositing a thin layer of copper inside the drilled holes, forming the conductive vias.

- Multilayer FPCB:

- Same equipment as for double-sided FPCBs, with the addition of the following:

- Lamination Press: Used to bond multiple layers of flexible substrates together with adhesive layers.

- Bonding Press: Used for bonding inner layers of the FPCB stack with copper foils.

- Laser Drilling Machine: Used for high-precision drilling of microvias in the multilayer stack.

- Copper Plating Line: Used for through-hole copper plating and subsequent copper buildup on the outer layers.

- Additional Imaging/Exposure, Etching, and Plating Equipment: Required for the outer layer circuits.

- Rigid-Flex FPCB:

- Same equipment as for multilayer FPCBs, with the addition of the following:

- CNC Milling Machine: Used for precise cutting and shaping of the rigid sections.

- Z-axis Registration System: Ensures accurate alignment between the rigid and flexible sections during lamination.

- Additional Drilling and Plating Equipment: Required for the rigid sections.

Please note that specific equipment may vary depending on the manufacturer’s capabilities, technology requirements, and production scale. The above list provides a general idea of the equipment commonly used for manufacturing different types of FPCBs.

What equipment is required to produce single-sided FPCB, double-sided FPCB, Multilayer FPCB, and Rigid-Flex FPCB simultaneously?

If you want to produce single-sided FPCBs, double-sided FPCBs, multilayer FPCBs, and rigid-flex FPCBs simultaneously, you would need a comprehensive set of equipment that can handle the different manufacturing processes involved. Here’s an overview of the equipment you would typically require:

FPCB Manufacturing Machine

If you want to produce single-sided FPCBs, double-sided FPCBs, multilayer FPCBs, and rigid-flex FPCBs simultaneously, you would need a comprehensive set of equipment that can handle the different manufacturing processes involved. Here’s an overview of the equipment you would typically require:

- Substrate Cutting Machine: Used for cutting flexible substrates into desired shapes and sizes.

- Imaging/Exposure Equipment: Used for transferring circuit patterns onto the substrates using photosensitive films or dry film resists.

- PCB Etching Machine: Used for chemically removing unwanted copper from the substrates to form the circuit patterns.

- Plating Equipment: Used for copper electroplating to enhance copper thickness and conductivity.

- Solder Mask Coating Machine: Used for applying a protective solder mask layer over the copper traces.

- Surface Finishing Equipment: Used for applying final finishes to the exposed copper surfaces (e.g., HASL, immersion gold, or immersion tin).

- Drilling Machine: Used for drilling holes in the substrates for component leads and vias.

- Electroless Copper Deposition System: Used for depositing a thin layer of copper inside the drilled holes to create conductive vias.

- Lamination Press: Used for bonding multiple layers of flexible substrates together with adhesive layers in multilayer and rigid-flex FPCBs.

- Bonding Press: Used for bonding inner layers of the multilayer and rigid-flex FPCB stack with copper foils.

- Laser Drilling Machine: Used for high-precision drilling of microvias in the multilayer stack.

- CNC Milling Machine: Used for precise cutting and shaping of the rigid sections in rigid-flex FPCBs.

- Z-axis Registration System: Ensures accurate alignment between the rigid and flexible sections during lamination in rigid-flex FPCBs.

- Copper Plating Line: Used for through-hole copper plating and subsequent copper buildup on the outer layers in multilayer FPCBs.

- Additional Imaging/Exposure, Etching, and Plating Equipment: Required for producing the outer layer circuits in multilayer FPCBs.

- Additional Drilling and Plating Equipment: Needed for producing the rigid sections in rigid-flex FPCBs.

It’s important to note that producing all these types of FPCBs simultaneously would require a significant investment in equipment and may involve complex manufacturing processes. It’s advisable to consult with specialized PCB manufacturing equipment suppliers or industry experts to customize a production line that suits your specific requirements and budget.