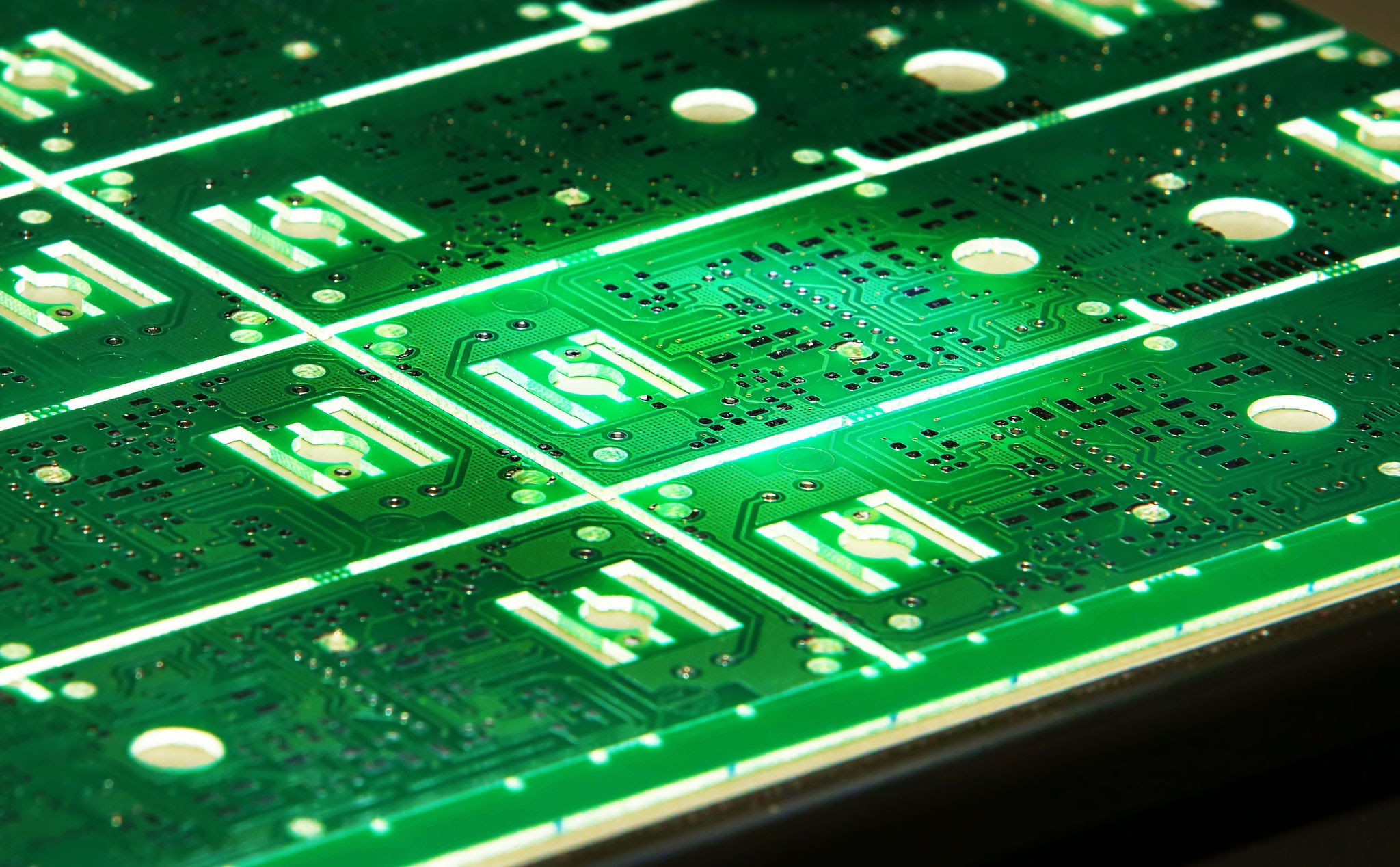

PCB etching is a delicate and critical process in the production of printed circuit boards. Technicians and quality control teams must regularly troubleshoot common issues to ensure smooth operation and high-quality output. This handbook provides a guide to identifying and fixing etching defects, addressing maintenance concerns, and ensuring consistent results across all stages of the process.

Identifying and Fixing Etching Defects

In PCB chemical etching, even minor defects can lead to significant issues in the performance and reliability of the board. Understanding how to identify and correct these issues is vital for maintaining high-quality production standards.

Over-Etching (Undercut Traces)

Over-etching occurs when the etching process continues too long, causing the removal of too much copper from the traces. This often results in undercut traces, which can lead to unreliable connections or breakage. To address over-etching:

- Check etching time: Ensure that the etching time is aligned with the specific requirements for the material and trace thickness.

- Adjust chemical concentration: A high etchant concentration can speed up the etching process, leading to over-etching. Ensure that the concentration matches the material specifications.

- Control etching rate: Lowering the etching rate by reducing the temperature or the etchant flow can help prevent over-etching.

Incomplete Etching (Residue Buildup)

Incomplete etching, often caused by inadequate exposure to the etchant, results in residue buildup or unetched copper areas. This defect can cause poor conductivity and circuit malfunctions. To resolve incomplete etching:

- Ensure uniform etchant coverage: The etchant solution should be evenly distributed across the PCB surface for consistent exposure.

- Agitate the etchant solution: Gentle agitation can help prevent residue buildup by ensuring the continuous flow of the etchant across the surface.

- Increase etching time: If the etching time is too short, increase it slightly to ensure complete copper removal.

Etchant Degradation and Maintenance

Etchants naturally degrade over time due to exposure to air and chemicals, which can affect the quality of the etching process. Regular maintenance is essential to ensure the longevity and effectiveness of etching solutions.

Monitoring pH and Specific Gravity

The pH and specific gravity of the etching solution are critical factors that influence the etching process. If the pH or specific gravity deviates from the optimal range, it can lead to inconsistent etching. Here’s how to monitor and maintain them:

- Regular pH testing: Use a pH meter to check the acidity or alkalinity of the etchant. For most etching processes, a pH range between 4 and 7 is ideal.

- Measure specific gravity: This will ensure that the etchant has the right concentration and density. Tools like a hydrometer can be used for accurate measurements.

Replenishment Strategies for Consistent Results

To maintain a stable etching process, replenish the etchant solution regularly. Over time, the active chemicals break down, and replenishment ensures that the etching quality remains consistent. Develop a replenishment schedule based on usage and solution degradation rates to optimize etchant performance.

Equipment Calibration for Precision

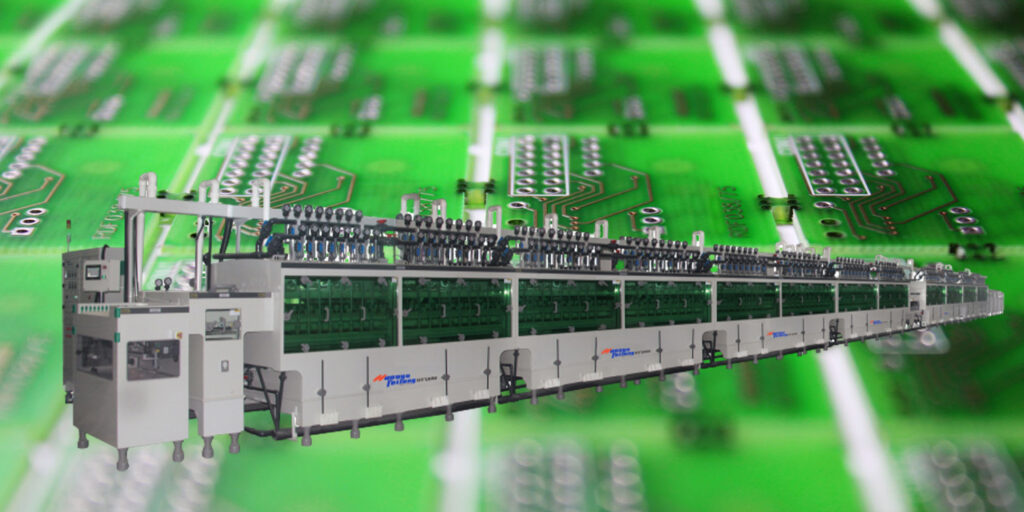

Calibrating your etching equipment regularly is crucial for maintaining consistent results. Without proper calibration, the system may produce incorrect etching widths or depths, leading to defective boards. Here’s how to ensure proper calibration:

- Nozzle calibration: Ensure that etching nozzles are clean and calibrated to the correct pressure to achieve consistent flow.

- Concentration monitoring: Regularly check the concentration of your etching solution to avoid too-high or too-low chemical levels, which can lead to defects.

Nozzle Clog Prevention

Clogged nozzles can cause uneven etching and poor quality. To prevent this:

- Regular cleaning: Periodically clean the nozzles to prevent chemical buildup.

- Filter the etchant solution: Use filtration systems to remove debris and particles that can block the nozzle openings.

Temperature Drift Compensation

Temperature fluctuations can affect the etching rate. If the temperature is too high or low, it can cause over-etching or under-etching. Use temperature compensation to ensure that the etching solution remains at the optimal temperature, typically around 40–50°C, depending on the chemistry used.

| Issue | Cause | Solution |

|---|---|---|

| Over-Etching | Excessive time or high etchant flow | Reduce time or control etchant flow |

| Incomplete Etching | Uneven chemical exposure | Agitate etchant, adjust exposure time |

| Clogged Nozzles | Build-up of debris | Clean nozzles regularly |

| Temperature Drift | Fluctuating temperature | Implement temperature control |

Material-Specific Challenges

Different PCB materials can pose unique challenges during the etching process. These challenges require specific attention to ensure optimal results.

Etching Issues with Flexible PCBs (Polyimide)

Flexible PCBs, particularly those made of polyimide, can be more challenging to etch due to their sensitivity to heat and chemicals. To address these issues:

- Control etching time: Flexible PCBs require less time in the etching solution to avoid warping.

- Use mild etchants: Strong etchants can damage the delicate polyimide layer. Choose mild, biodegradable etchants for a safer process.

Adhesion Problems on High-Tg Substrates

High-Tg substrates (with a high glass transition temperature) can sometimes have adhesion issues when etching. This can result in poor copper bonding and failure to properly etch. To solve this:

- Pre-treatment of the substrate: Perform a thorough cleaning or surface treatment to improve adhesion.

- Adjust etching conditions: Use a more concentrated etching solution and slightly higher temperatures to promote better adhesion on high-Tg substrates.

Preventive Maintenance Checklists

To maintain high-quality PCB etching and prevent common issues, implement a preventive maintenance routine. Ensure that daily, weekly, and monthly inspections cover all essential equipment components.

Daily, Weekly, and Monthly Inspection Routines

- Daily: Clean nozzles, check chemical levels, and monitor pH levels.

- Weekly: Calibrate equipment, check temperature settings, and replace filters if necessary.

- Monthly: Perform a full system check, including etching tank inspections, calibration of chemical solutions, and thorough nozzle cleaning.