Key Features to Prioritize for Small-Scale Production

Compact Benchtop Etching Machines

Compact benchtop etching machines are ideal for small-scale PCB prototyping. These machines offer flexibility, space efficiency, and ease of use, making them perfect for startup environments. Many models are designed to handle small batch runs, ensuring quick iterations with minimal overhead.

| Feature | Advantage |

|---|---|

| Size | Space-saving for small workshops |

| Automation | Minimizes manual work, increasing efficiency |

| Precision | Suitable for intricate designs |

| Cost | Affordable option for low-volume production |

Low-Consumption Etchant Recycling Systems

Etchant recycling systems are essential for reducing chemical waste and cutting long-term costs. These systems recycle the etchant solution, allowing it to be used multiple times, thus conserving resources while maintaining effectiveness.

Balancing Speed vs. Accuracy in Prototyping

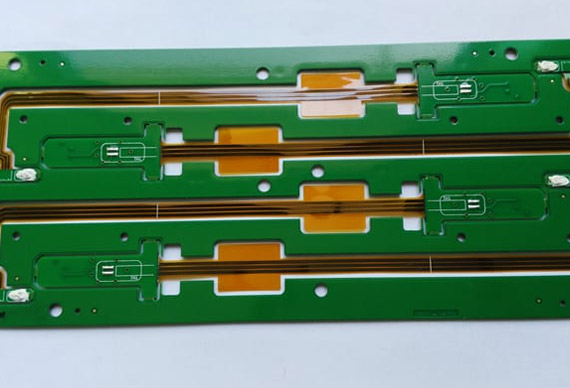

One of the most critical factors in PCB prototyping is striking the right balance between speed and accuracy. While high-speed etching may save time, precision is often more important in prototyping, as the goal is to validate designs quickly and accurately.

Batch Processing vs. Single-Panel Throughput

Batch processing allows for the simultaneous etching of multiple PCBs, increasing efficiency and output. However, for rapid prototyping, single-panel throughput can be more cost-effective and space-efficient, especially for small runs or testing individual designs.

Tolerance Requirements for Rapid Iteration

Tolerance refers to the allowable deviation in PCB measurements. When iterating quickly, it’s crucial to ensure the etching machine can maintain the required tolerances. High-precision equipment may be more expensive but is necessary to produce prototypes with high reliability.

Cost Analysis: New vs. Refurbished Equipment

When purchasing PCB etching machines, deciding between new and refurbished models can significantly impact the budget. New equipment typically offers cutting-edge technology, warranties, and fewer maintenance issues. However, refurbished machines may offer substantial savings, particularly when bought from reputable sources.

| Aspect | New Equipment | Refurbished Equipment |

|---|---|---|

| Cost | Higher initial investment | Lower upfront cost |

| Warranty | Often includes warranty and support | May have limited or no warranty |

| Technology | Latest features and capabilities | Older models may lack advanced features |

| Longevity | Expected to last longer with proper use | May require more maintenance |

ROI Calculation for Low-Volume Shops

For low-volume PCB shops, calculating the return on investment (ROI) for etching equipment is crucial. Consider both direct costs (purchase price, maintenance) and indirect savings (time saved, reduced material waste). A well-planned investment in machinery will lead to higher profitability in the long run.

Maintenance Costs of Older Models

Older etching machines may incur higher maintenance costs due to wear and tear. Keeping track of these costs is important for evaluating the overall long-term investment. It’s advisable to set aside a budget for regular maintenance and consider whether purchasing a new machine would be more cost-effective in the long run.

Top Suppliers for Entry-Level Systems

When sourcing entry-level PCB etching systems, some top suppliers include:

- LPKF: Known for their high-quality PCB milling and etching machines, LPKF offers both affordable and advanced systems for small shops.

- Technic Inc.: Specializes in PCB etching solutions and provides customizable equipment for various scales of production.

- DIY Kits: For startups on a tight budget, DIY kits can offer an entry-level etching solution. These kits often include basic etching tools and require manual involvement.

For more insights on PCB suppliers, you can visit the following resources:

Future-Proofing Your Investment

When choosing an etching system, consider future scalability. Look for modular upgrades and options that will allow the machine to handle more complex PCB designs as your needs grow. Future-proofing ensures that your initial investment remains valuable as your production requirements increase.

Modular Upgrades for Advanced PCB Designs

As your PCB designs evolve, you may require additional capabilities. Many modern etching machines offer modular upgrades, allowing users to enhance features such as etching speed, precision, and the ability to handle larger panel sizes. This flexibility helps you stay competitive in a rapidly advancing market.