Chemical etching is a widely used process in the manufacturing industry for producing intricate patterns and designs on stainless steel surfaces. This technique offers a high degree of precision and efficiency, making it a preferred choice for industries ranging from aerospace to medical device manufacturing.

What Is Chemical Etching Stainless Steel?

Chemical etching, also known as chemical milling or photochemical machining (PCM), is a process that uses acid-based solutions to selectively remove material from a stainless steel surface. This is often done to create detailed, high-precision patterns without the need for mechanical cutting tools. Unlike traditional methods, chemical etching can produce designs with tight tolerances, intricate geometries, and burr-free edges, which are especially crucial in industries like aerospace, automotive, and medical devices.

Definition and Core Principles

Chemical etching of stainless steel involves several key principles:

- Precision: Highly detailed and intricate designs can be achieved.

- Efficiency: The process is faster and often more cost-effective than mechanical cutting methods.

- No Material Stress: Unlike mechanical cutting, chemical etching does not introduce stress or distortion to the metal.

- Environmentally Friendly: The process can use less energy and produce less waste compared to traditional machining.

How Acid-Based Etching Works on Stainless Steel

Acid-based etching solutions, such as Ferric Chloride or Nitric Acid, are applied to the stainless steel surface after the desired pattern is created using photolithography. The chemical solution dissolves the unmasked areas of the metal, leaving behind the etched pattern. This process is highly controlled to ensure precise etching and prevent over-etching.

Key Advantages Over Mechanical Cutting

- Intricate Details: Unlike laser or mechanical cutting, chemical etching can achieve extremely fine and detailed patterns.

- Burr-Free Edges: The process produces clean edges without the risk of burrs, reducing the need for additional finishing work.

- No Tool Wear: Unlike mechanical cutting, which involves tool wear, chemical etching remains consistent throughout the process.

Step-by-Step Process Breakdown

The chemical etching process follows a well-defined sequence of steps to ensure accuracy and quality.

Material Preparation (Cleaning, Coating)

Before etching, stainless steel surfaces must be cleaned to remove oils, dirt, and oxidation. This ensures that the etching solution can properly react with the material. A light coating, such as photoresist, is then applied to protect areas of the metal that will not be etched.

Photolithography and Mask Alignment

Photolithography is used to create precise patterns on the material. A mask or photoresist layer is applied to the stainless steel, and UV light is used to expose the areas that need to be etched. The unexposed sections are then washed away, leaving the desired pattern behind.

Etching Solutions (Ferric Chloride, Nitric Acid)

Ferric Chloride and Nitric Acid are commonly used etchants for stainless steel, depending on the desired results. These solutions dissolve the exposed metal in a controlled manner, creating the precise etching pattern.

Post-Etching Treatments (Passivation, Rinsing)

Once etching is complete, the metal undergoes post-etching treatments. Passivation helps to enhance the metal’s resistance to corrosion, while thorough rinsing removes any remaining etching chemicals to ensure a clean and finished product.

Material Compatibility and Selection

Different grades of stainless steel offer unique properties that make them suitable for various applications. It’s important to select the right material for etching to achieve the desired quality and performance.

Best Stainless Steel Grades for Etching (304, 316, 430)

- 304 Stainless Steel: Offers excellent corrosion resistance and is ideal for a wide range of applications.

- 316 Stainless Steel: Known for superior corrosion resistance, particularly in marine environments.

- 430 Stainless Steel: Provides good formability and is commonly used for decorative applications.

Thickness Guidelines (0.1mm to 2.0mm)

Chemical etching is effective for a range of material thicknesses. Stainless steel sheets from 0.1mm to 2.0mm are typically used, with thinner gauges providing greater precision for more intricate designs.

Surface Finish Options (Brushed, Mirror, Satin)

The surface finish of the stainless steel can impact both the etching process and the final appearance. Popular finishes include:

- Brushed: Provides a smooth, matte finish.

- Mirror: High gloss, reflective surface.

- Satin: A soft, semi-gloss finish.

Industrial Applications of Etched Stainless Steel

Chemical etching is employed across many industries, thanks to its ability to create precision components with complex designs.

Aerospace (Fuel Cell Components, Sensor Meshes)

In aerospace, etched stainless steel is used for manufacturing components like fuel cell parts and sensor meshes that require high precision and durability in extreme conditions.

Medical Devices (Surgical Tools, Implant Markings)

Medical devices such as surgical tools and implant markings benefit from the high precision and biocompatibility of etched stainless steel.

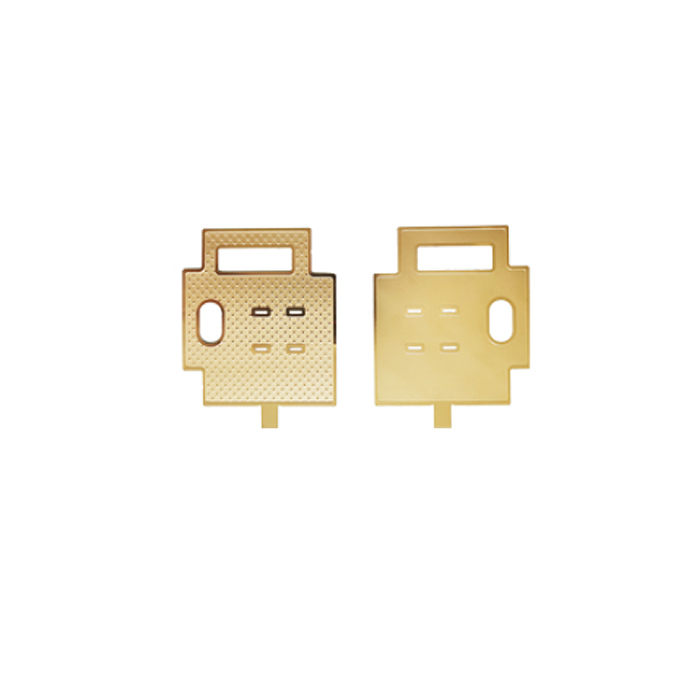

Automotive (EMI Shields, Decorative Trims)

Automotive applications, including EMI shields and decorative trims, use chemical etching to create lightweight, durable parts with intricate designs.

Solving Common Etching Challenges

While chemical etching is a highly effective method, there are certain challenges that need to be addressed for optimal results.

Over-Etching and Undercutting Prevention

Over-etching occurs when the etching solution penetrates beyond the desired areas, while undercutting refers to the removal of material beneath the mask. Both can be prevented through careful control of time, temperature, and chemical concentration.

Burr-Free Edge Requirements

Achieving burr-free edges is one of the key advantages of chemical etching. However, if not controlled properly, the etching process can leave small unwanted projections. Ensuring the right etching conditions and solution strength helps avoid this issue.

Environmental Compliance (Waste Acid Disposal)

Proper disposal of etching solutions is essential to meet environmental regulations. Etching operations must implement appropriate waste management systems to neutralize and safely dispose of used chemicals.