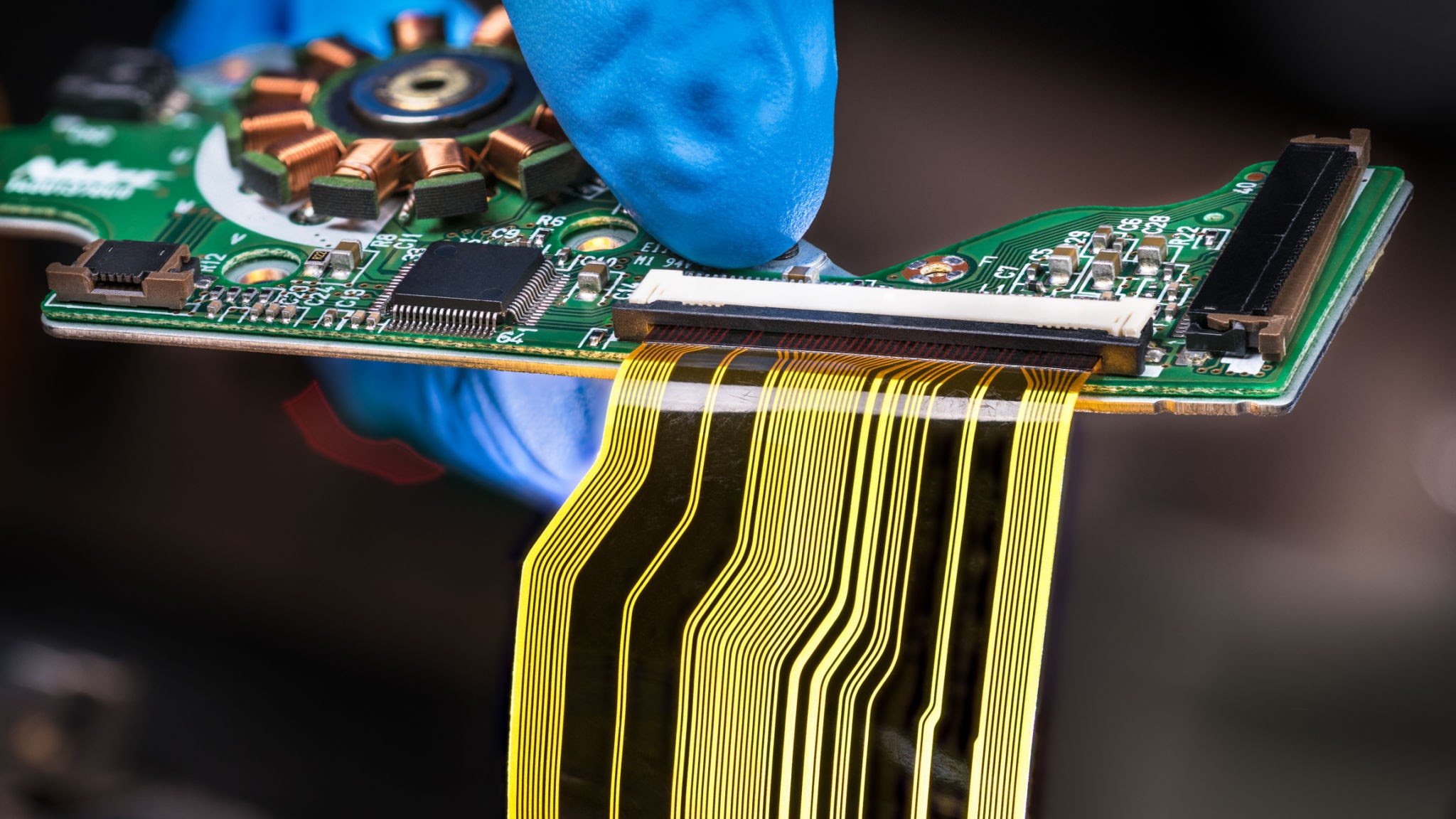

Flexible Printed Circuit Boards (FPCBs) are thin, flexible electronic circuits that are used in a wide range of applications, including smartphones, tablets, wearable devices, and automotive electronics. The manufacturing process for FPCBs involves several steps, including design, material selection, and fabrication.

- Design: The first step in FPCB manufacturing is designing the circuit layout. This involves determining the placement of components, the routing of traces, and any necessary connections or vias. Specialized software is used to create the circuit design.

- Material Selection: FPCBs are typically made of a flexible substrate material, such as polyimide or polyester film. The choice of material depends on the specific requirements of the application, including flexibility, temperature resistance, and durability.

- Copper Cladding: The flexible substrate is coated with a layer of copper on one or both sides. This is typically done through a process called electroless copper plating or electroplating, where a thin layer of copper is deposited onto the substrate surface.

- Imaging: A photosensitive material, called a photoresist, is applied to the copper-clad substrate. The circuit pattern is then transferred onto the photoresist using a photomask and exposure to ultraviolet light. This process allows for the creation of the desired copper traces and pads.

- Etching: After the imaging process, the exposed copper areas are etched away using an etching solution, leaving behind the desired circuit pattern. The photoresist is then removed, and the substrate undergoes a cleaning process to prepare it for the next step.

- Surface Finishing: Surface finishing techniques are employed to protect the exposed copper traces and pads and provide better solderability. Common surface finishes used in FPCB manufacturing include immersion gold, HASL (Hot Air Solder Leveling), and OSP (Organic Solderability Preservatives).

- Assembly: Once the FPCBs are fabricated, they can be assembled with electronic components. This involves placing the components onto the FPCB and soldering them in place. The assembly process can be performed using automated equipment or manual labor, depending on the complexity and volume of production.